Regarding labeling materials, we have several options for laser techniques, including laser marking, engraving, or etching. However, laser marking stainless steel requires special attention when it comes to labeling.

This metal alloy contains at least 10% chromium, making it corrosion-resistant. While laser marking is a safe method for labeling designs on stainless steel, engraving requires some special techniques before labeling can occur.

In this article, we’ll focus on stainless steel laser marking and delve into the various grades of stainless steel; that are suitable for laser marking. We’ll cover everything from A to Z, so if you want to learn more, keep reading!

Stainless Steel and Its Grades

Stainless steel is an alloy metal. It contains iron, carbon, and other elements such as chromium, nickel, and molybdenum with at least 10% chromium.

Chromium material makes it a corrosion and rust-free alloy. It also has a shiny, reflective surface. That enables it a popular material for decorative and functional applications.

Stainless steel comes in different grades, each with unique properties and applications.

Grades of stainless steel

Understanding the different grades of stainless steel is critical when it comes to laser mark stainless steel. These grades of stainless steel can affect the quality of the marking and the level of contrast between the mark and the material surface.

Therefore, choosing the suitable grade of material for the intended application is critical to ensure the best results.

It comes in various grades, but the most common are 304, 316, and 430.

- Grade 304 is the most commonly used and is suitable for various applications.

- 316-grade is more corrosion-resistant and is often used in marine environments or for medical devices.

- Grade 430 is less corrosion-resistant and used in applications where appearance is less of a priority.

| Grade | Composition | Application |

| 304 | 18% chromium, 8% nickel | Food and beverage industry, kitchen appliances, architecture, automotive trim |

| 316 | 16-18% chromium, 10-14% nickel, 2-3% molybdenum | Marine applications, medical devices, chemical processing equipment |

| 430 | 16-18% chromium | Automotive trim, kitchenware, indoor architecture |

| 201 | 16-18% chromium, 3.5-5.5% nickel, 0.8-1.2% manganese | Kitchenware, sinks, food processing equipment |

| 409 | 10.5-11.7% chromium | Automotive exhaust systems, heating and ventilation ducts |

| 440C | 16-18% chromium, 0.95-1.2% carbon, 0.75% molybdenum | High-end cutlery, bearings, surgical instruments |

Benefits of laser marking on stainless steel

It offers many benefits, including durability, precision, and versatility. These advantages make it an attractive option for industries that require permanent, high-quality markings on stainless steel products.

- It creates permanent and durable markings on stainless steel. Laser marking’s high precision and accuracy resist wear, corrosion, and fading.

- It allows for precise and accurate markings on stainless steel, down to the finest details. That is particularly relevant in industries where accuracy and precision are critical, such as the medical and aerospace industries.

- It is also versatile for marking all types, including logos, text, and barcodes.

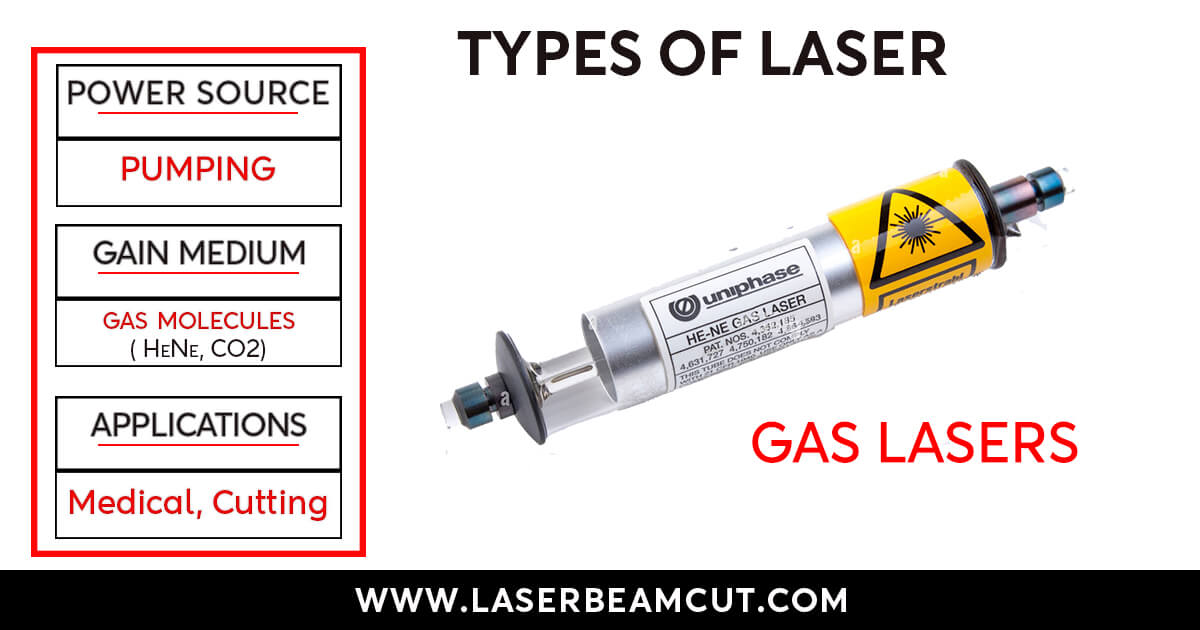

Types of Lasers Used to Mark Stainless Steel

When it comes to marking stainless steel, laser technology has proven to be highly effective due to its precision and versatility. One key factor to consider is the type of laser used in the marking process. Here are the main laser types used for marking stainless steel:

Fiber Lasers:

These lasers are the most commonly used for marking stainless steel. They are highly efficient and can produce high-quality marks on various materials, including stainless steel.

Fiber lasers use solid-state optical fibers as a medium to generate the beam.

It is a highly concentrated and powerful beam that can quickly and accurately mark stainless steel surfaces.

CO2 lasers:

We use CO2 lasers to mark stainless steel, although they are less known than fiber lasers. The beam produces by utilizing a gas mixture of carbon dioxide, nitrogen, and helium.

With a longer wavelength, CO2 lasers are better suited to marking stainless steel with higher carbon content.

Nd: YAG lasers:

Nd: YAG lasers are another option for marking stainless steel. These lasers use a solid-state laser crystal as a medium to generate the beam.

Nd: YAG lasers are highly precise and produce high-quality marks on stainless steel, but they are also more expensive than fiber or CO2 lasers.

It’s important to note that each type of laser has its own set of advantages and disadvantages, and the best option for marking stainless steel will depend on a variety of factors, including the desired mark quality, the speed of the marking process, and the type of stainless steel being marked.

Laser marking process for stainless steel

Marker machine uses a laser beam to produce a thin layer mark design on the steel.

It involves the following steps:

Step 1: Clean the stainless steel.

Before laser marking, it is critical to clean stainless steel with a soft cloth. You can remove any moisture from the material’s surface using a dry cloth and then wipe it with a damp cloth.

If the surface is still dirty, use soapy water to scrub it. Allow the stainless steel to dry before marking.

Step 2: Choose the Correct Laser Marking Machine

It is essential to select the correct laser marking machine for stainless steel.

Some machines may take multiple passes to get dark mark results without pretreatment. Use marking spray and mark the metal in one go for the best results.

Step 3: Adjust the laser settings

The next step is to adjust the laser settings according to the desired outcome.

Optimizing the machine settings involves testing them on a scrap piece of stainless steel before marking the final product.

Step 4: Laser Marking the Stainless Steel

After adjusting the laser settings, we can mark the stainless steel using a laser beam. We focus the laser beam on the intended marking area and perform the marking process in a well-ventilated area to prevent hazardous fumes. After completion, we should cool down the stainless steel before handling it.

Applications of Laser Marking Stainless Steel

Laser marking is a popular technique to mark various materials, including stainless steel. It is durable and corrosion-resistant, making it an ideal candidate for laser marking.

The different applications of laser marking on stainless steel are

- Identification tags

- Barcodes

- Serial numbers

- Company logos

- Medical devices

- Aerospace components

- Automotive parts

- Electronic components

- Jewelry engraving

- Decorative designs

Conclusion

I hope you are now well aware of laser marking stainless steel. In conclusion, it offers many benefits, including durability, precision, and versatility. It creates permanent and durable markings on stainless steel, making them resistant to wear, corrosion, and fading.

Choose the appropriate grade of stainless steel for the application to ensure the best results.

To learn more about laser marking on stainless steel, including its comparison with laser engraving, keep reading our informative blogs, and fill out the contact form to request to join our email newsletter for updates.

FAQs

1. Can stainless steel be laser engraved?

Ans: Yes, it is possible. There are some factors to consider when laser engraving stainless steel.

- As the laser marking process does not remove any material from the surface, it is safe to mark it.

- If we need to engrave stainless steel, this process removes the upper layer of the material. It affects the rusting features of that material.

- Use laser marking wherever rust prevention is necessary for that material. Alternatively, you can use laser engraving or etching if it’s not a big issue.

2. How do you remove laser marks from steel?

Ans: There are many ways to remove laser marks on steel, including polishing, sandblasting, and chemical treatments such as acid etching or passivation. Consult a professional for the most effective solution.

3. Will laser engraving cause rust on stainless steel material?

Ans: Laser engraving can potentially remove the protective oxide layer on stainless steel, which may affect its rust resistance. The impact depends on factors such as the type of stainless steel and engraving parameters used.