Fiber lasers are the most common laser type; used in laser machines and other applications. Industrial manufacturing processes like engraving, cutting, welding, and drilling operations apply these lasers to perform these tasks. Medical and educational industries use these lasers in their applications.

Due to this, you should know its basics: What is it? How it works and its applications. Let’s get started studying it in depth.

Before studying fiber lasers and their working process, some of their related terminologies are important, and you should be familiar with them. These terms are Fiber material, photons(light), wavelength, refraction, refractive index, and doping.

- Fibered material has the property to refract light.

- Fibers are as thin as the diameter of two human hairs.

- Photons are light particles that travel in waves.

- Wavelength represents the color of light in the optical spectrum

- Refraction means refracting of light waves from the material’s surface

- Refractive index — mean the angle of refraction

- Doping – to enhance refractive index, materials are doped (coating) with other materials to maximize their performance

What is Fiber Laser?

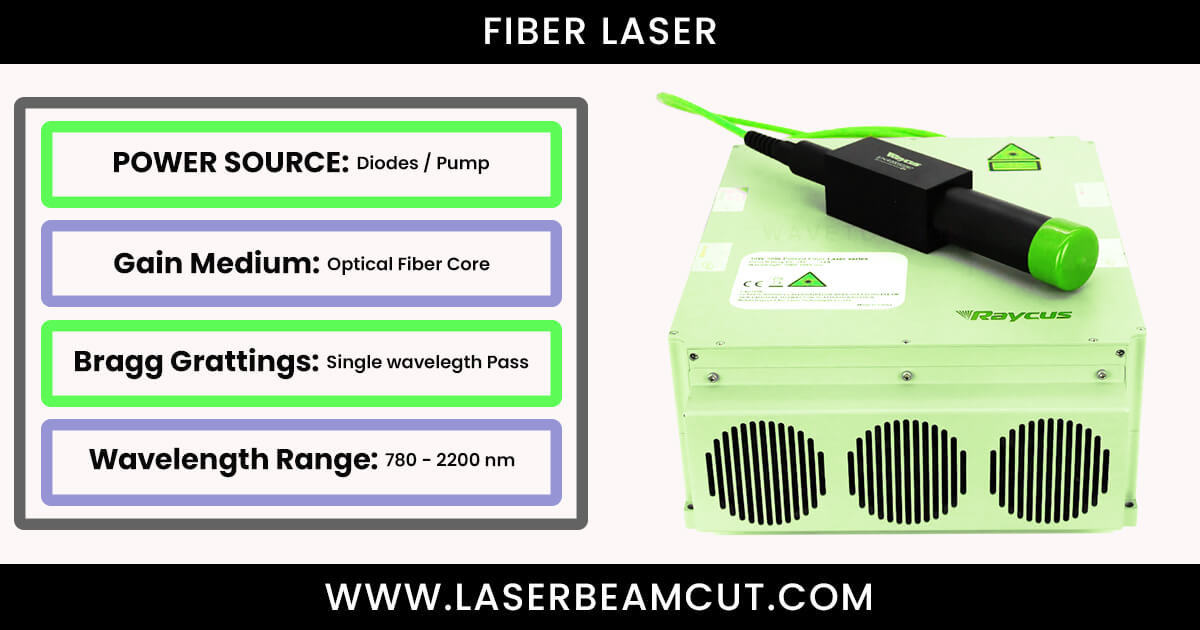

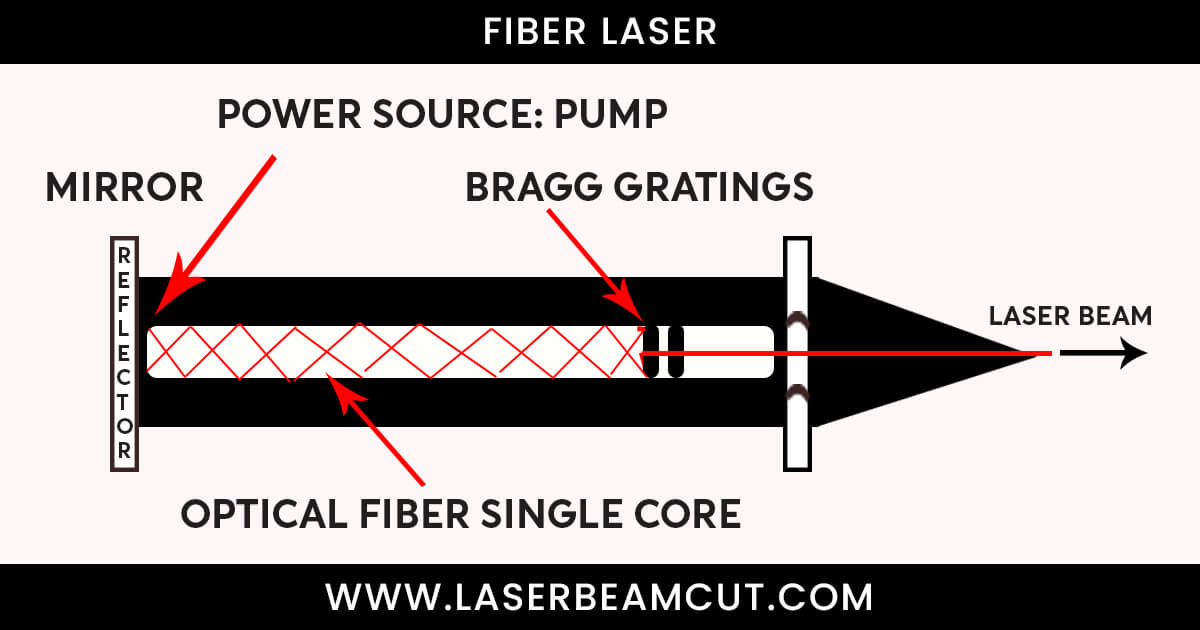

To understand the fibered laser devices, first, divide their components. It contains a gain medium, power source, resonator, and brag gratings.

The gain medium of these devices is an optical fibers core that is Doped with rare earth materials such as Erbium, Ytterbium, or Neodymium to enhance its refraction of photons.

These devices use diodes as a power source. These diodes emit light and pump into the core of the optical fibers in the gain medium to stimulate gain medium molecules.

Brag grating at the fiber’s core allows it to pass a single wavelength of photons and transmit to others. Due to this high-power beam is generated.

Their wavelength is between 780nm to 2200 nm.

These lasers have many applications, including medical and industrial use. They offer many advantages over other laser types, including high power and speed.

How does a Fiber Laser Works?

When the diode pumps light into the gain medium, optical fiber molecules are stimulated and enter the Fibers Core. This core is Doped with rare earth materials.

Fiber Brag Grating devices are added to the fiber’s core to amplify its light and allow a specific wavelength of light molecules to travel in the fiber’s core. In the end, it creates a high-power beam.

Fiber Laser Types

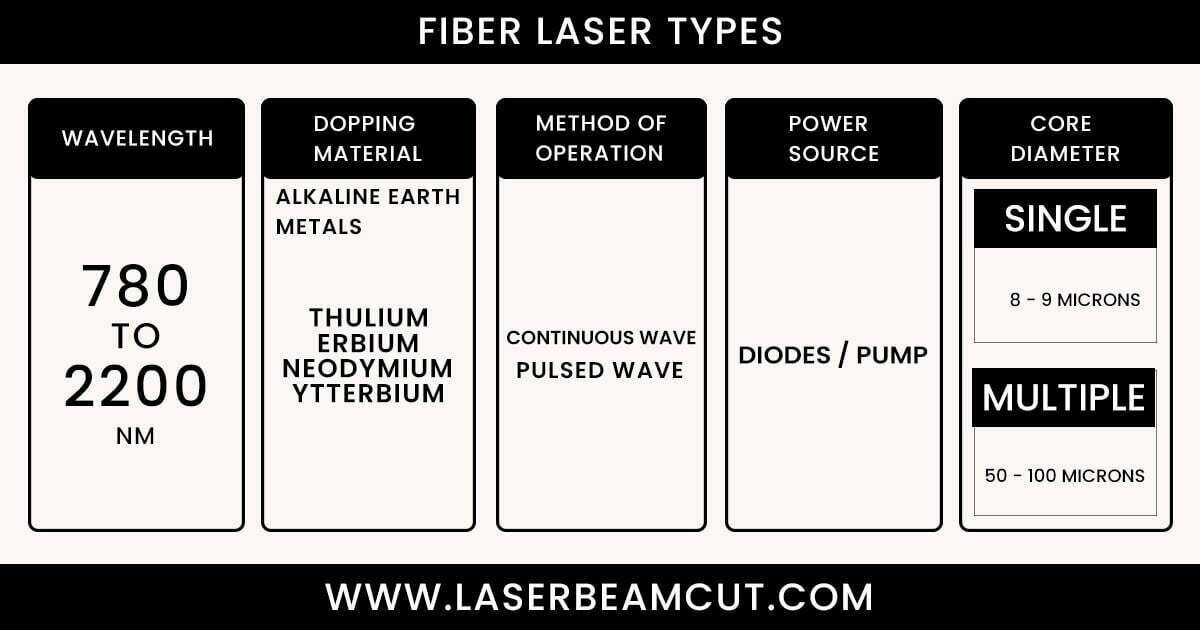

Their types relate to the intensity of the lasers, which depends on the wavelength, optical fibers doping material, core size, power source, and method of operation.

Have a look at these factors in detail.

Wavelength

These laser’s wavelength range is between 780nm to 2200 nm. It represents the intensity of laser light in the electromagnetic radiation spectrum.

The range 780 nm and 2200 nm falls in the infrared region and are invisible to the human eye.

Optical Fiber Dopping Material

Each doped material generates a specific wavelength. Each has unique applications.

Dopping Material | Wavelength (nm) | Application |

Neodymium | 780 – 1085 | Educational Kits |

Ytterbium | 1060 – 1100 | Cutting, engraving, Marking, and welding |

Erbium | 1500 – 1600 | Optical components testing, spectroscopy, etc. |

Thulium | 1900 – 2200 | Medical Treatments like kidney stones breaking process |

Method of Operation

These operates in a two ways.

- Continuous wave

- Pulsed wave

Continuous Wave Fiber Lasers

In this type of laser, the beam releases a continuous wave from the device. Due to this intensity and power of the laser remains constant.

These lasers use to perform high-power operations like cutting, welding, etc.

Pulsed wave fiber lasers

This type of laser is in which a beam releases pulse waves from the laser device. The pulses are powerful and intense, which causes them to be short bursts of light.

These lasers are best for engraving, spot welding, and other applications for precise results.

Power Source

The laser devices release low-power or high-power beams depending on the power source.

- Low-power fiber lasers use where precise results have priority over time.

- High-power fibers laser uses where needs high cuts and weld parts in the manufacturing industry.

Core Diameter

Optical fibers core in which stimulated molecules travel are single-mode or multi-mode cores. Based on these modes, core diameter depends.

- Single core diameter is near up to 8 – 9 microns. These modes’ lasers emit high-quality beams that are best for manufacturing applications.

- Multi-core diameter is near up to 50 – 100 microns. These modes’ lasers emit low-quality beam compared to single-mode fiber lasers.

Fiber laser Applications

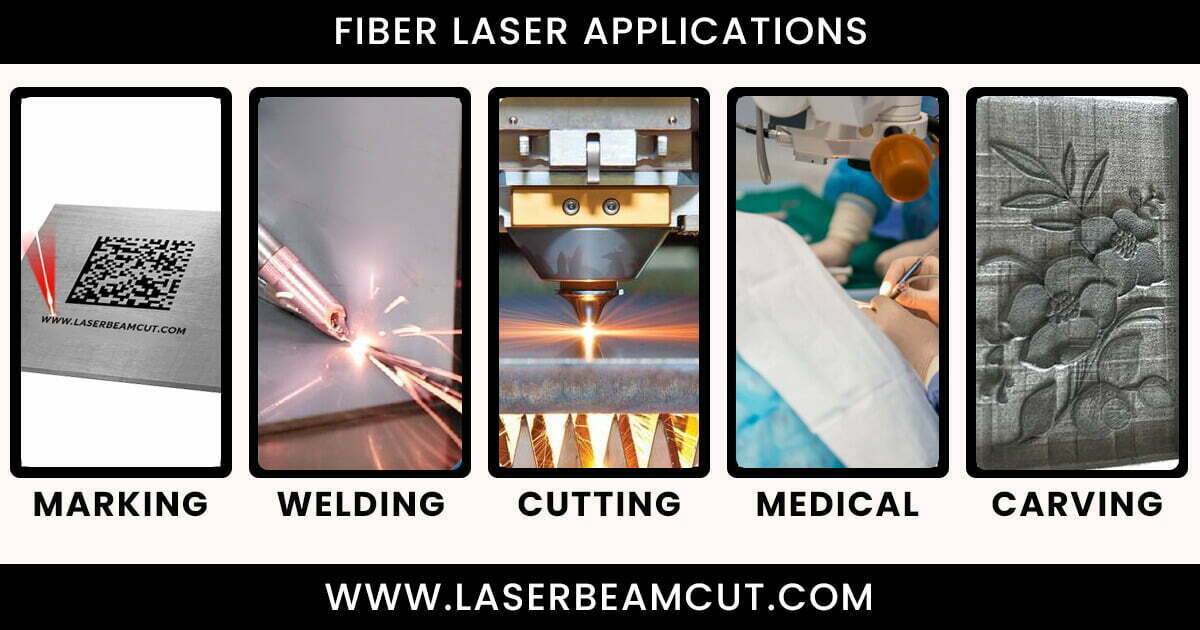

Fiber lasers have various applications as it releases a wide range of laser outputs. Most of their applications are in manufacturing industries.

Some applications in manufacturing industries of fiber lasers are

Fiber Laser Marking Machine

The Fiber lasers have a wavelength of 1060 – 1100 nm and use to mark symbols, logos, and patterns by laser marking machines. In these lasers, the fibers’ optical core is Doped with Ytterbium materials.

These laser marker machines can mark plastics and metals. These machines’ marks are permanent and have high contrast marks.

The Fibers laser also are used in engraving, annealing, and etching machines.

Fiber Laser Welding Machine

Continuous fiber lasers have high-power beams; that can weld different thick metals. On the other hand, Pulsed fiber lasers have pulse power output and use to weld materials by spot welding machines.

The technology allows for a short lead time, precision, and no contact with materials. It also produces more high-quality welds than other traditional welding processes.

Fiber Laser Cutter Machine

These lasers are widely used in cutter machines to cut materials for precise and quality results.

These types of cutter machines can cut metal of thickness up to 20 mm. These machines can cut wood, plastics as well as metal materials.

Medical Industry

In the medical industry, fiber lasers use in many diagnostic and operation procedures. Breaking stones in the kidney and endoscopic treatments for diagnosing are the applications of fiber lasers.

Advantages of Fiber Laser

Some benefits of these devices are

- Have a small spot size, so ideal for precise and detailed working applications

- Can travel long distances with minimum loss as compared to others

- Have continuous high-power beams; that is best for cutting and welding applications

- Small-size and lightweight devices

Comparison of fiber laser VS other Laser Types

Each type has different characteristics due to its unique composition and gain mediums.

Fiber VS CO2 Lasers

The fiber laser’s wavelength range is 780nm to 2200 nm, while the CO2 laser wavelength is 9600 – 10600 nm.

Parameter | Fiber’s Lasers | CO2 Lasers |

Gain Medium | Optical Fibers | CO2 gas |

Wavelength | 780nm to 2200 nm | 9600 – 10600 nm |

| Beam Spot | small | large |

| Maintenance Need | less | high |

Material Capability | Metals (mild steel, copper, brass), leather, wood, etc. | Metals (Steel, Aluminum), glass, wood, etc. |

As fiber lasers have less wavelength as compared to CO2 lasers, fiber lasers are best for metal process applications that need less power and small-size beams.

MOPA fiber lasers use for non-metal operations and color marking and engraving.

On the other hand, CO2 lasers have big beam diameters and high power, so they are used in the manufacturing process of steel and aluminum-like materials.

Fiber VS Diode Lasers

Parameter | Fiber’s Lasers | Diode Lasers |

Gain Medium | Optical Fibers | Semi-conductor |

Wavelength | 780nm to 2200 nm | 550 – 950 nm |

| Beam Spot | small | Very small |

| Maintenance | less | Very less |

Material Capability | Metals (mild steel, copper, brass), leather, wood, etc. | Metals and non-metals, except glass |

The wavelength range of fiber lasers is 780nm to 2200 nm, while the Diode laser’s wavelength is 550 – 950 nm.

Diode lasers are small in size and have low power compared to Fiber lasers.

Due to this low power, these devices are not for industrial applications such as Fiber lasers application.

Conclusion:

Fiber lasers use rare-earth-doped optical fibers core as a gain medium and diodes as a source pump light. These devices use to perform different tasks in the medical and manufacturing industries.

Frequently Asked Questions (FAQs)

1. What makes fiber lasers so important?

Ans: These devices give a variation of output. Due to this, widely used in manufacturing and medical application.

2. What are rare earth metals that are Doped with optical fibers?

Ans: These rare earth materials are Erbium, Ytterbium, Neodymium, Thulium, and many more.

3. Can fiber lasers engrave gold?

Ans: Yes, it is possible to engrave gold using pulsed wave fibers lasers.