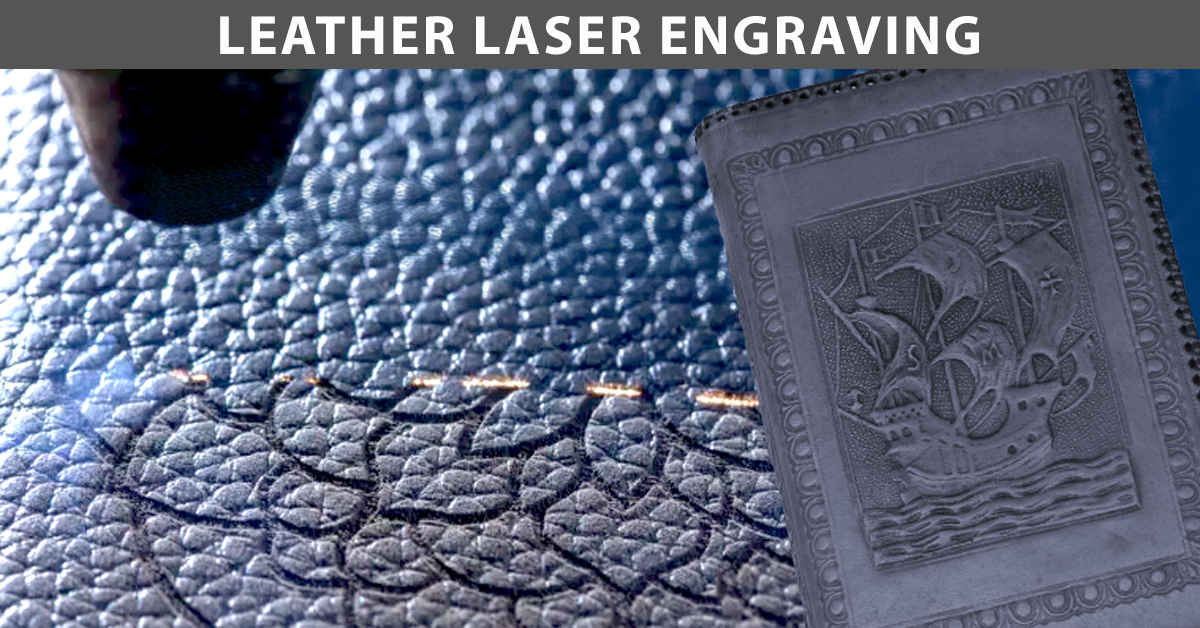

Leather laser engraving is a process that involves employing a laser beam to create intricate designs, texts, and patterns. It enhances its appearance and ensures precision.

Leather – a flexible yet durable material. The skin of animals, especially cattle, is used to make it. In today’s advanced and fashion-oriented age, these materials have many uses. However, lasers have greatly transformed numerous fields in countless ways, making them an incredible tool.

In this article, we have covered a range of related aspects by describing the whole process of leather laser engraving. I hope this answers all your queries. Are you interested in diving into this fascinating study? Let’s explore it together.

How does leather laser engraving work?

Laser engraving leather is a simple process done with a laser engraving machine.

Leather Laser Engraving process Step-by-step:

- Select leather product type.

- Choose the appropriate laser for this leather product.

- Provide design to the engraver.

- Set the machine parameters – Speed, Power, etc.

- Place the product on the machine’s bed.

- Allow the engraver to start the engraving process.

- It heats the surface and removes the material by evaporating it.

- An air assist helps to remove smoke from the bed.

- In the end, a high-quality engraved design is produced on the surface.

The engraving is a similar process to marking, etching, and cutting. However, there is a subtle difference.

In engraving, a beam heats the leather surface to vaporize the surface material, leaving our desired design imprinted on it.

Etching leather follows a similar process, but in this case, the laser beam melts the leather surface instead of vaporizing it. So, it gives an etched design with slightly less depth than an engraved one.

In the marking process, no material is removing took place, as in the engraving or etching processes. A design is printed on the product surface by laser marking sprays.

In contrast, when cutting leather, the machine’s beam heats the surface to a point where it cuts through the product.

Types of Leather

Leather is a versatile material prized for its durability, comfort, and timeless appeal. It is primarily derived from the hides and skins of animals, with cattle being a common source. Leather comes in various types, each with distinct characteristics and uses. A brief description of various types of leathers available in the market is as follows:

Full-grain leather:

Full-grain leather, renowned for its exceptional quality, is crafted from the uppermost layer of the hide. It preserves the inherent grain patterns and imperfections.

It enhances its durability and promotes graceful aging with time. This type of leather finds its predominant application in premium-grade products.

Top-grain leather:

Top-grain leather is also made from the top layer but is sanded and treated to remove imperfections. It’s smooth, pliable, and commonly used in furniture, wallets, and belts.

Genuine leather:

Genuine leather is a broad term, and it refers to real leather that’s not the top layer. It can vary in quality, with some products being quite durable while others are less so. It’s commonly used in upholstery and accessories.

Bonded Leather:

Bonded leather is crafted by binding together leather scraps using adhesive and then applying a layer of polyurethane. While it offers affordability, it generally exhibits lower durability compared to other leather types.

Nubuck Leather:

Nubuck leather is crafted from top-grain leather that undergoes a sanding process to achieve a luxurious velvety surface. While it possesses a soft and appealing texture, it demands meticulous care to safeguard against stains and scuffs.

It finds frequent application in the production of shoes and handbags.

Suede Leather:

Suede is made from the underside of the hide and is known for its soft, fuzzy texture. It’s less durable than full-grain leather and requires special care to maintain its appearance. Often used in clothing and accessories.

Exotic leather:

Exotic leather includes materials like alligator, crocodile, ostrich, and snake skin. These leathers are unique and luxurious, with distinct textures and patterns. They are often used in high-end fashion and accessories.

Vegan leather:

It is a synthetic alternative, appealing to those seeking cruelty-free options in fashion and accessories.

These types of leather are not suitable for laser engraving. It is due to vinyl content in the composition of products that can produce harmful fumes under lasering operations.

Analysis of leather types for the engraving process:

Among the leather types mentioned earlier, full-grain leather stands out as the optimal selection for laser engraving. This preference arises from its inherent natural grain, which greatly amplifies the intricacy of designs and patterns.

Synthetic leathers are not suitable for laser engraving. It is due to vinyl content in the composition of products that can produce harmful fumes under lasering operations.

Laser types to Engrave Leather

Several laser techniques commonly engrave leather. Each one of them offers distinct advantages and is suitable for various applications.

Here are some widely used laser techniques for engraving leather:

CO2 Laser Engraving:

CO2 (carbon dioxide) lasers are popular for engraving leather due to their versatility. They work by vaporizing the material’s surface, leaving a permanent mark.

These can create highly detailed designs, intricate patterns, and text on leather. The fashion industry commonly uses these engravers for personalizing and branding leather products.

Fiber Laser Engraving:

Fiber lasers are known for their precision and speed. They use fiber-optic technology to create fine engravings on leather surfaces.

These engraver machines are used for industrial applications, such as engraving leather goods with serial numbers or barcodes.

UV Laser Engraving:

UV (ultraviolet) lasers are suitable for engraving on synthetic or coated leather materials. These engravers offer high-resolution markings and enable the creation of unique designs on leather surfaces. UV laser engraving is common in the production of high-end leather items.

Nd: YAG Laser Engraving:

Neodymium-doped yttrium aluminum garnet lasers are known as Nd: YAG lasers. These are versatile and cheap tools for engraving various leathers.

They are famous for their capability to produce deep engravings. We can use them for deep engraving designs on belts, jackets, etc.

Femtosecond Laser Engraving:

Femtosecond lasers are super-fast and immensely precise. They are used for intricate and purpose-based leather engravings, making them appropriate for artistic and detailed designs. Luxury leather goods and fine art applications use this technique.

Galvo Laser Engraving:

Galvo lasers use a moving mirror system to rapidly direct the laser beam, allowing for fast and precise engraving. Manufacturers typically use them for batch production of leather items such as wallets, bags, and phone cases.

Analysis of Laser Type

The choice of laser technique largely depends on the particular requirements of the leather engraving project, including

- Type of leather

- Proposed design complexity

- Production demand

- Extent of engraving needed

Each technique has its strengths, making it essential to select the most suitable one for the task at hand.

Why Laser Engraving?

Laser engraving is the preferred method for leather engraving due to the following technical factors.

- High-intense beams enable intricate designs and sharp details on leather.

- Works on various leather types, thicknesses, and design complexities.

- The non-contact process eliminates material damage risks. It is crucial for delicate leather goods.

- This technique is highly efficient and takes less time to complete the process.

- It ensures consistent quality for small-scale customization or large-scale production. It reduces waste and production time.

- Work by computer-controlled programmability instructions. It allows for easy design adjustments, enhancing accuracy.

Laser-Engraved Leather Products and the Consumer Market

Here are some reasons for the high demand for laser-engraved leather products:

Personalization:

Consumers are increasingly opting for unique and personalized items. Laser engraving permits not only customization with names, initials, and special dates but also with meaningful designs.

This personal touch enhances the value of leather products like wallets, bags, belts, and purses.

Corporate Branding:

Businesses now usually use laser engraving to affix their logos or branding information on leather items, such as promotional gifts and merchandise.

This demand is much in line with the trends in the corporate gifting and marketing sectors.

Fashion and Luxury Markets:

The fashion industry continues to incorporate laser-engraved leather designs in high-quality leather goods.

Engraved patterns and designs have the potential to elevate aesthetics and add a personalized touch to luxury products.

Art and Craft:

Laser-engraved leather has a separate fan base in the crafting and DIY communities. Artists and crafters employ laser engraving to create intricate designs on leather for various artistic and aesthetic purposes.

Functional Benefits:

Engraved leather products may offer dividends for functional benefits. It can include easing the identification of personal items (e.g., luggage tags) or increasing the grip on certain items (e.g., engraved handles on leather tools).

Eco-Friendly Practices:

It is an eco-friendly alternative to conventional methods of engravings. It is because it produces only minimal waste and does not use toxic chemicals.

Eco-Friendly practices aligns with the increasing demand for environmentally reasonable products.

Technology Advancements:

Advancements in laser technology have resulted in making the engraving process more accessible. It is also cost-effective for businesses irrespective of their sizes, further enhancing demand.

10 Quality Enhancement Strategy for Leather Laser Engraving Success

In the competitive world of leather laser engraving, achieving excellence requires a strategic approach. Here’s a comprehensive strategy that can help your business not only stand out but also thrive:

1. Invest in Top-Notch Equipment:

Begin by investing in high-quality laser engraving equipment. It’s essential to have the right tools for the job. Ensure that your equipment can handle a variety of leather types and maintain optimal laser settings for each.

2. Prioritize Material Quality:

Use only the best-quality leather materials for your engravings. Superior materials contribute significantly to the overall quality of your products.

3. Develop Design Expertise:

Cultivate expertise in designing. Continuously test and refine your engraving techniques to stay ahead of the competition.

4. Implement Stringent Quality Control:

Establish and uphold stringent quality control protocols. These measures guarantee that every product attains the pinnacle of craftsmanship excellence.

5. Offer Customization Options:

Give your customers diverse customization options. The ability to personalize their leather products will set you apart.

6. Expand Your Product Range:

Work on expanding your product range. Offering a wider variety of leather goods will attract a broader customer base.

7. Embrace Eco-Friendly Practices:

Adopt eco-friendly practices in your production process. Consumers appreciate environmentally responsible businesses.

8. Provide Exceptional Customer Care:

Being really good at helping customers makes them happy and more likely to buy from you again and tell others about your brand.

9. Invest in Branding and Marketing:

Create a strong image for your business that people can recognize and trust. Spend some money on advertising to make more people aware of what you offer in the market.

10. Stay Informed About Industry Trends:

Keep a close eye on industry trends and emerging technologies. Being aware of what’s happening in your niche can help you adapt and innovate.

Conclusion

Leather laser engraving is an eco-friendly process to engrave leather products such as wallets, belts, jackets, etc. We’ve explored diverse leather types, laser techniques, and tips and tricks.

To thrive in this realm, invest in quality equipment, prioritize material excellence, and master design. Exceptional customer care, effective branding, and industry awareness are vital.

We discuss the “10 reasons for the high demand for Laser-Engraved Leather Products in the Consumer Market” at the end of the article.

FAQs (Frequently Asked Questions)

1. How thick is laser engraving leather?

Ans: The thickness of laser engraving leather depends on the wattage of the laser. You can cut through leather anywhere between 1/16” and 1/4” in thickness, and with two passes, it may be possible to cut slightly thicker material.

2. What power laser for leather?

Ans: The power of the laser for engraving leather, especially thick or hard ones, is crucial. For a CO2 laser machine, the minimum power rating required to effectively engrave leather is 40W. So, for leather engraving, experts recommends to use a laser machine with a power rating of at least 40W.

3. Is PU leather safe to laser engrave?

Ans: PU leather is a synthetic or faux leather. It should not be suitable for lasering operations such as cutting, engraving, or etching due to the potential release of toxic fumes. These emitting harmful fumes can be dangerous to both health and the environment.

4. Should you wet leather before laser engraving?

Ans: Moisturized leather becomes more flexible, which makes the etching process easier and more effective. However, it’s important to wet the leather only enough to render it pliable, as excessive moisture may have adverse effects.

So, yes, you should wet leather before laser engraving, but with the caveat of not making it too wet.

5. What is the difference between embossed and laser-engraved leather?

Ans: Embossed leather is created through a stamping process. Where heat and high pressure are used to create patterns or designs on the leather hide. On the other hand, laser-engraved leather utilizes a computer-operated lasering process that is contact-free.