Permanent label marks are used in industries to identify tools or machine parts. Due to these labels on materials, the machine operator or machines can quickly identify them. Laser marking is a good choice for creating label marks on material surfaces. These marks may be barcodes, text, images, or any symbol. So, you should want to know ” what is laser marking “. Let’s go to its inside to explore this amazing technology.

If we adopt different methods to create these identification marks on tools, there may be a chance to reduce the strength of materials. Stay in the safe zone; everyone prefers this technology for these purposes.

Let’s go into this exciting study of laser marking systems. Are you ready?

What is Laser Marking Systems?

Laser marking is a process to create permanent marks on the surface of materials for their identification purposes by using concentrated and low-power laser beams. This process performs with a laser machine that includes an oscillator, a scanning mirror, and a focusing lens.

To get high-contrast and high-precision marks on the surfaces of materials, laser marker machines alter the surface color of the material. Unlike other types of marking, this doesn’t involve removing any material from the surface.

Laser Marking Types

We can go with four ways to do this.

- Carbon Migration

- Foaming

- Annealing

- Coloration

Carbon Migration

Laser carbon migration is a process for marking metals and alloys containing high carbon content.

In this process, the laser beam alters the chemical composition of the material’s surface and forces the carbon content to rise to its surface.

In the end, a dark mark appears on the surface of your workpiece.

Foaming

Laser foaming is a process in which the laser melts the material without vaporizing it.

The result is the generation of bubbles that creates an appealing look or texture on the workpiece.

This process uses on non-metallic surfaces such as polymers.

Annealing

Laser annealing is a method to mark steel and other types of metals. In this process, a laser beam separates the surface layers of the metal, oxidizing them and leaving a permanent mark on the workpiece.

Coloration

Laser coloration can use on metals and plastics to produce colorful marks. The pulse width and frequency of the laser are specifically modified to create different colors on the workpiece surface.

Laser Marking Process

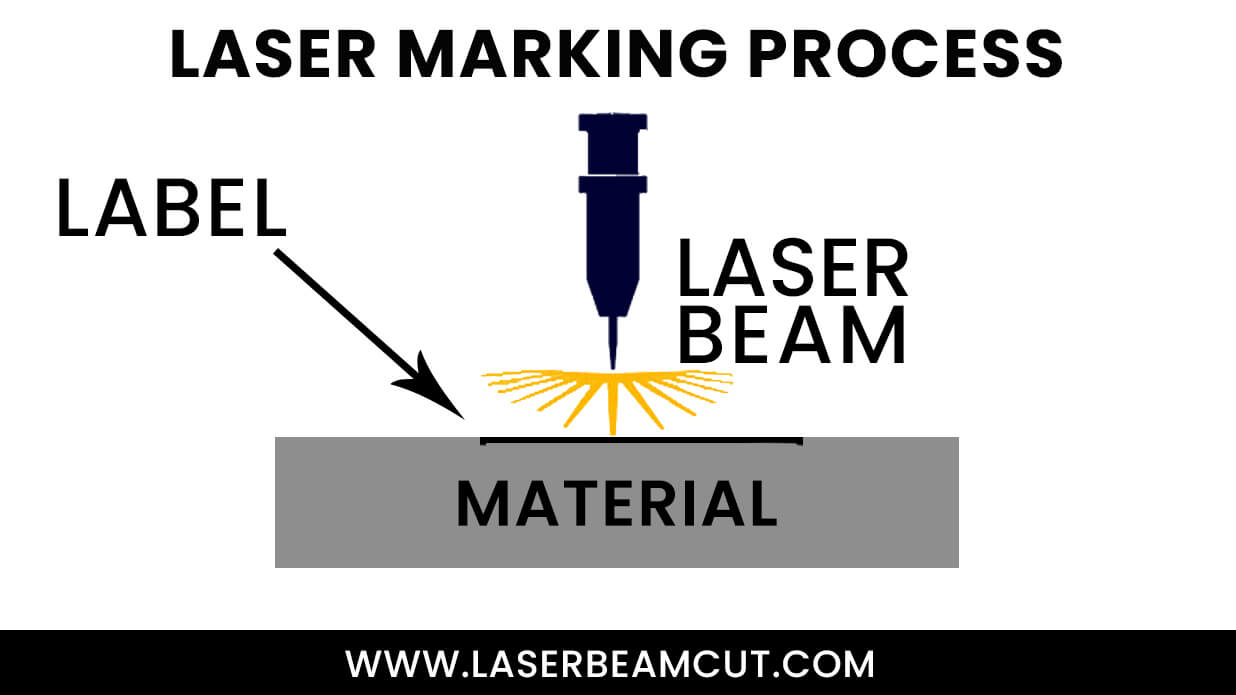

This marking technology uses lasers to create precise, permanent marks on components. The lasers generate a narrow beam of high-energy light directed at the material’s surface using mirrors.

As light interacts with the surface of an object, it transfers heat energy from the beam to that surface. Due to this, the appearance and properties of a surface material change.

The concentrated beam of light targets specific areas on the material, ensuring precise, high-contrast marks. These marks are permanent, and a scanner or other imaging device can easily read these marks.

This marking process is ideal for applications where a high degree of accuracy is required.

Laser Marking Comparison with Laser Engraving, Annealing, and Etching

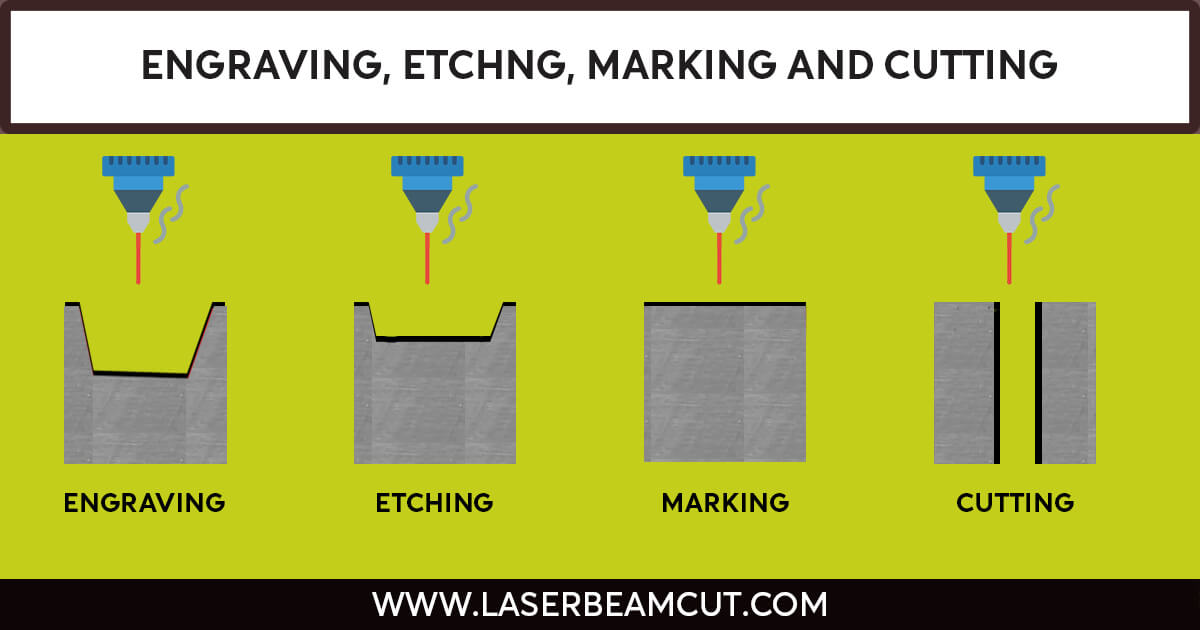

Creation of permanent labels on material surfaces, a process called laser marking.

Etching, annealing, and engraving are other related terms used to describe similar methods, but they can be different by the depth involved in these methods.

Since laser marking, annealing, and engraving and etching are similar processes. The key differences between these terms are working depth and machine power.

To get a brief knowledge about these terms, take 10 minutes to read this blog. laser etching vs engraving vs marking.

List of Laser Marking Machines:

These machines depend on the laser type that uses in these machines. To get a brief knowledge about Lasers and their types, take 5 minutes to read this blog. What is Laser and its Classifications?.

Laser marker machines are used to label materials by laser marking process. These are of many types depending on the work nature and material properties.

The top 5 types of laser marker machines are

CO2 Machines

These machines create barcodes, serial numbers, and logos on metals and other surfaces.

Fiber Machines

These machines are used for hard metal marking. Their power source is 5-10 watts. Color marking is also possible with this type of machine.

UV Laser Marker

Cold-marking labels on plastics, glass, or ceramic materials are an application of UV marker machines. These machines are ideal for labels for all sorts of products.

Green Laser Marker

These machines are used for highly reflective material marking. Their power source is 20-50 watts. Electronic device marking is the best option for these machines.

MOPA Laser Marker

Multi-coloring label materials are the applications of MOPA laser marker machines. Mobiles IMEI numbers labels on the casing are examples of these laser machines.

Applications of Laser Marking

Industrial and commercial products require labels. Laser marking helps create these labels, including model and serial numbers, QR codes, bar codes, part numbers, logos, dates, and other information.

Traceable information needs quality control, and for this task, laser marking is one way to create permanent identification markers on various components.

Silicon wafers are examples—of photovoltaic cells, electronics, smart cards in automobiles, and more. This way, you can easily trace back and solve possible problems quickly.

Benefits of Laser Marking

It plays a role in manufacturing processes, helping businesses track their products, minimize counterfeiting, improve quality, and more. It helps you make precise markings with high precision, saving you time and money.

So, what are some benefits of this technology?

High Lead Time

Laser marking technology helps prevent the loss of tools and makes it easy to identify them, thus reducing production time.

Durable Marks

Laser markings can withstand abrasion, heat, and acids. It makes them the best choice for durable marking needed for reliable product tracing. You won’t have to fear the mark fading off because it’s permanent.

Mass Production

In mass production, similar designs can be marked on the surface of materials by laser marker machines when parts move through an assembly line.

Variety of Materials

A variety of materials can easily label marked by different laser marker machines.

Low Maintenance Process

As this is a non-contact marking process, there is no chance of mechanical material wear or tool damage to the machine. Because these marker machines require less maintenance than manual or Mechanical marking techniques, they are more economical.

Disadvantages of Laser Marker Machines

This systems also have several limitations.

First, it can only scan on the X and Y axes.

Secondly, they cannot process hard or low ignition point materials.

Due to these drawbacks, potential users might turn to traditional methods that tend to provide a more human touch that reaches beyond the two-dimensional plane.

Conclusion

We label materials, such as images, text, or barcodes, on the surfaces of materials with laser marker machines. It has four types: carbon migration, foaming, annealing, and coloration.