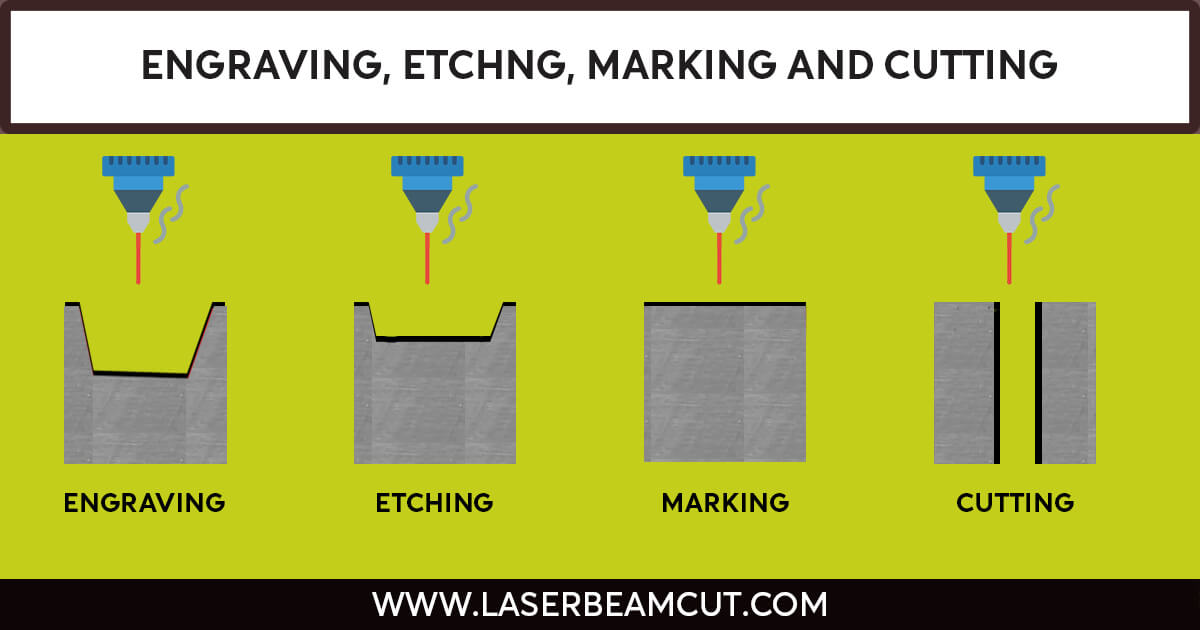

We use laser machines to make permanent and deep marks on the material surface. These machines give different outcomes Mark, Etch, and Engrave marks. Let’s go to analyze laser etching vs engraving vs marking.

Laser machines work on material surfaces for engraving, marking, and etching purposes. However, all three processes have similar functionality. All three methods have their unique applications.

So the question arises; What is the main difference between these three terms? And which one is best for our application?

This article explains the differences between these related terms and discusses their similar operations: cutting and embossing. In the end, discuss factors that must consider before selecting these methods.

Laser Etching VS Marking VS Engraving

First, I want to give you the basics of these operations. Then we will study their relations with each other.

Laser Marking

The Laser marking is a process of permanent labeling of products by oxidizing their surface color using low-power laser beams.

The mark is produced by only altering the material’s color and does not involve any removal of the material surface.

Mostly, used to label manufactured parts with serial numbers and QR codes by laser marking.

To perform laser marking, we can go with four ways.

- Carbon Migration

- Foaming

- Annealing

- Coloration

If you want to know more about laser marking, read this blog.

Laser Engraving

This process vaporizes the surface by using a high laser beam on a material to create the engraved design.

Laser engraving classifications

Depending on the engravers machine’s capability of material removal, divided into four classes:

- laser ablation

- deep laser engraving

- convex laser engraving

- concave laser engraving.

If you want to know more about laser engraving, read this blog.

Laser Etching

Etching achieves by melting the material surface using a high laser beam. Laser etching working depth is not more than 0.0001 inches or 2.4 micro-meters.

It is similar to laser marking but used where long-lasting marks are needed.

If you want to know more about laser etching, read this blog.

Comparison between Laser Marking, Laser Engraving, and Laser Etching

At this point, you are now familiar with these terms. Now it’s time to study their relationship with each other. All these processes need to create permanent labeling of products. We will compare each term with another to get a clear concept of these terms.

The Cutting Process shows that it cuts or shapes the materials.

Laser marking, engraving, etching, and cutting operations can perform from a single machine. Machine parameters vary for each process to engrave, etch, or mark design on the material surface. These parameters are

Machine Parameters | Marking | Etching | Engraving |

Process | Oxidizing surface | Melting Surface | Vaporizing surface |

Working Depth | Surface method | 0.001″ (inches) | 0.001″-0.125″ (inches) |

Power Source | Low | Moderate | High |

Speed | High-speed | Low-speed | Low-speed |

Material Removal | NO | YES | YES |

Abrasion Resistance | Low | Moderate | High |

Applications | Barcodes, numbers etc | Name plaques on plates, cups, tools etc | Lether, wood carving designing |

The main difference between laser marking, etching, and engraving is the working depth and material process. To make permanent labeling of products, we use these three methods.

Laser marking is the surface phenomenon of oxidizing color to left marks. While Laser etching and engraving are subtractive methods as they remove materials from the surface to engrave or etch design.

Engraving VS Marking

Laser engraving is the method by which material vaporizes by a high-power laser beam to engrave design on the material surface.

While in laser marking, no material removal process took place. It oxidizes the surface color to leave dark marks on it.

Engraving VS Etching

Both processes remove materials by laser beams to engrave or etch the design on the material surface.

But etching melts the material surface to perform this task. While engraving vaporizes the surface with a high laser beam to engrave the design.

Marking VS Etching

The laser marking process leaves dark marks on the surface by just oxidizing color.

While etching makes etching the design on the surface by removing material by melting the surface with the moderate power laser beam.

At this point, you are familiar with these terms and can relate each process to the others. But you may still be unfamiliar with some of their similar techniques. So let’s discuss laser cutting and embossing.

Laser Cutting

Laser cutting cuts materials by using high laser beam power. Cutting and Engraving have the same methods but different outcomes due to the laser focal lens.

- Laser cutting has a longer focal lens to cut materials.

- Laser engraving has a shorter focal lens to engrave material design.

Laser Cutting Methods

There are four ways to cut materials with laser cutters.

- Sublimation cutting

- Melting Cutting

- Reactive Cutting

- Stealth Dicing

Embossing

It is a process of creating a raised image, text, symbol, or pattern design o the surface of the material by compression with the help of any press.

Mostly embossing is used in product packaging designs, lather products, stamps, etc.

Which is best for our application? Engraving, Marking, Etching, Embossing, or Cutting

Selecting the appropriate process for your application depends on your needs and material properties. But few factors you must consider before the operation starts.

- Material type (Melting point, surface type, thickness, etc.)

- Life of marking (for the long last marking, the recommendation is to go with laser engraving)

- Strength of material (If there needs to be no compromise on material strength, so avoid laser etching or engraving marks – When material removes by these processes, it affects material strength)

These are common factors that much include during the selection of labeling techniques. You can also use embossing on the material surface after laser marking to beautify the design without affecting material strength.

Conclusion

All three laser operations are use for permanent labeling of products. All processes can perform from a single laser machine but all these processes have different parameters.

Laser cutting and embossing processes are also discuss in this blog.

FAQ: (Frequently Asked Questions)

Q1: As laser marking marks are permanent, can we remove them from the material surface?

Ans: Yes. It is possible to remove these marks by sanding the material surface.

Q2: Is etching better than engraving? ( Etching vs Engraving )

Ans: It depends on your need and the properties of the material. But etching needs less time to etch design than engraving as in etch process, less material removes.

Q3: What are the examples of embossing?

Ans: The embossing examples are on product packaging design like medical, tools, and machine packaging.

On a credit card, our name and other information are also an example of embossing.