We engrave the material’s surface to create permanent deep marks on it. We can go with two options: first by manual methods of engrave designs or by laser engraving process.

Laser engravers are an increasingly popular manufacturing tool due to affordable laser engravers machine in the designers’ and small businesses.

Do you need to engrave your nameplate with a beautiful design?

Or are you looking to engrave-design your company desk table with a logo? Or do you want to engrave any symbol on metal?

It is all possible through the laser engravings process. How? Let’s see!

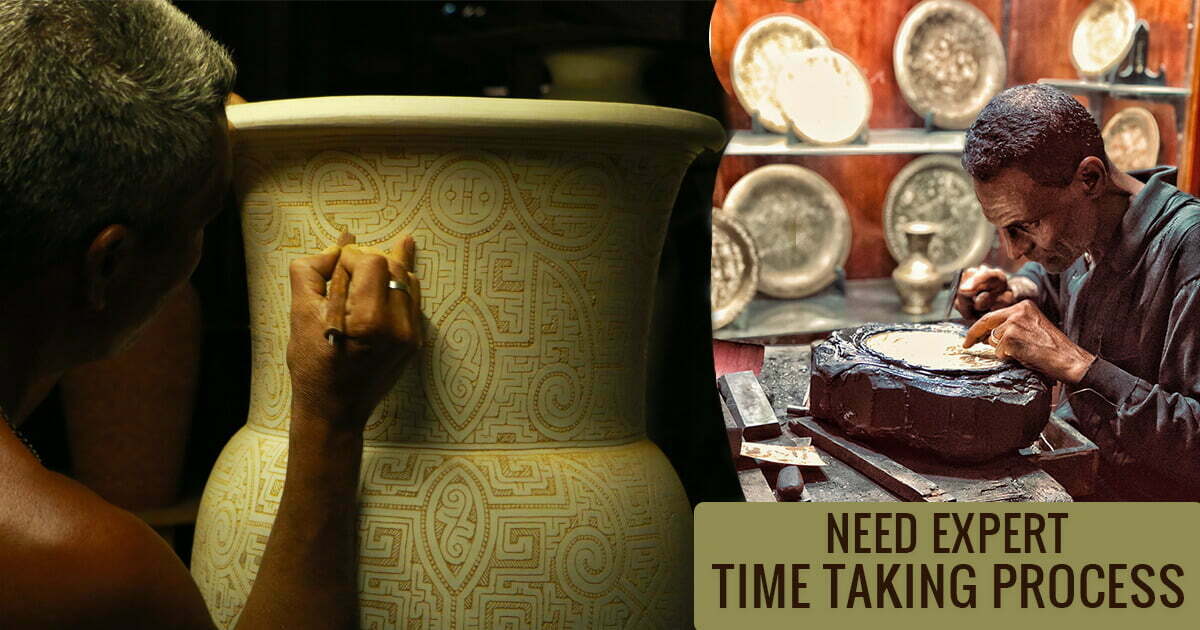

Why is manual engraving being abolished now?

The first appealing thing for a human is probably the design.

Man always tries to improve the visual look, so years ago technique introduces; to make designs attractive with the help of engraved designs.

That was manual engravings, so it’s a very time taking process and needs an expert to do.

So we need some techniques that have high accuracy, are fast, and are possible for mass production.

So laser engraved designs was introduced in 1978. This technology is improving day by day as technology changes.

We will talk in-depth about it but now look at the basics of laser technology.

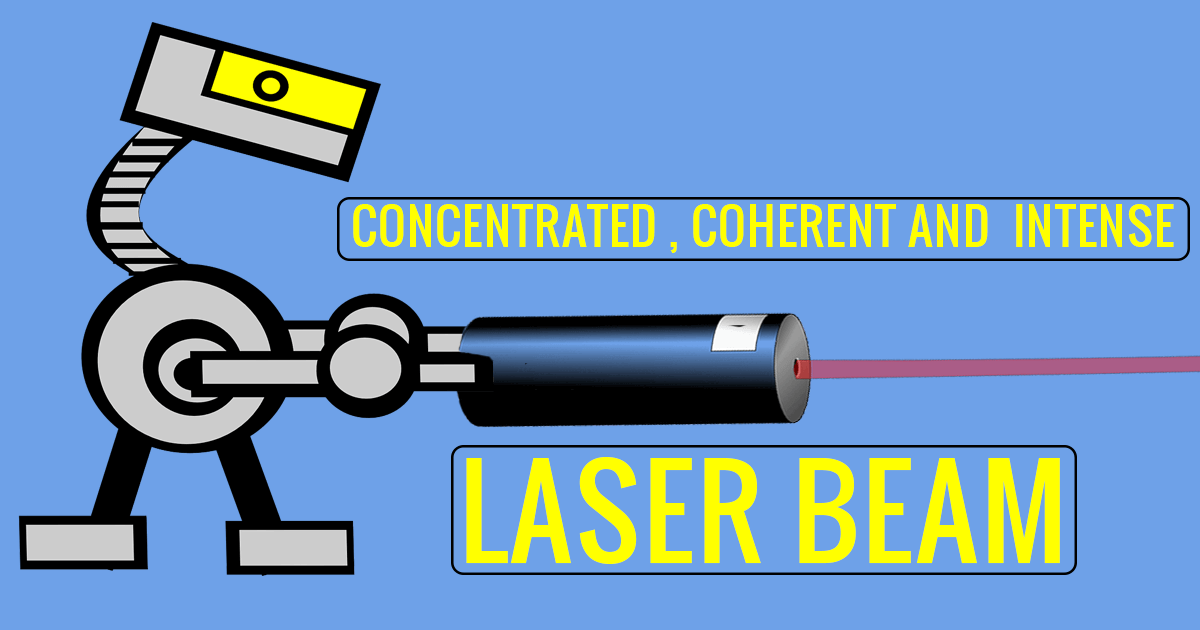

What is Laser? (Light Amplifier)

The laser is an optical device that generates intense beams of coherent light. It does this by using stimulated emission to create a laser beam.

Lasers are of 5 types and upon these classifications, laser applications depend.

Types of laser

- Gas Lasers

- Solid state Lasers

- Fiber lasers

- Dye lasers

- Semiconductor lasers

How is Laser Light Different From Normal Light?

The laser is a device that gives an amplified, single-color source of light. This ray of light from this does not go broader or weaker as most sources of illumination do.

A laser makes the beam much more concentrated, coherent, and intense, therefore applicable for cutting metals and welding materials together. But laser technology is not just limited to cutting and welding!

Cancer treatment and eye diseases ( like glaucoma by targeting individual cells with precision and accuracy) are also applications of laser technology.

| Characteristics | Ordinary Light | Laser Light |

| Mono Chromatic | No | Yes |

| Coherent | No | Yes |

| Directional | scattered | focused |

To get depth knowledge about Laser. ( What is laser? and laser classification based on safety norms).

What is LASER Engraving?

Throughout the years, laser engraved technology has advanced. Its purpose is to make a design (image, logo, or texture) on any surface (gold, silver, steel, or any material) with engrave process. But what is it?

The laser engravers are a CNC or manual laser machines that uses a (Fiber, UV, or CO2) laser beam to cut and engrave (2D or 3D) designs on the surface of materials.

It is the method that imposes the design by removing the surface on the material by using the laser beam, which can be called a substracted manufacturing method.

It is a way to create sharp, crisp designs with permanent, deep marks that can not be changed or removed. So make sure before doing this.

Laser Engraving Classifications Depending upon Material Removal:

Depending on the engravers machine’s capability of material removal, divided into four classes:

- laser ablation

- deep laser engraved process

- convex laser engraved process

- concave laser engraved process

Types of Laser Engravings

There are three types to engrave materials.

- CNC Laser Engrave machines

- Rotary Engrave machines

- Diamond drag engrave machines

How does It work (step by step)?

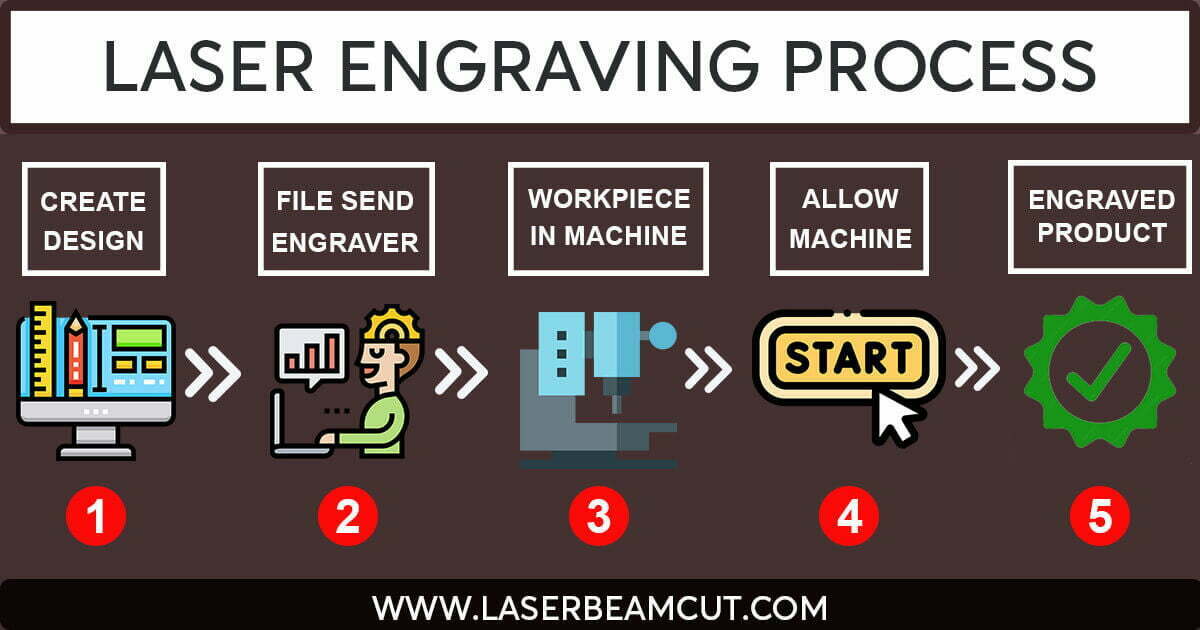

- The first step is to make a design on the software ( Inscape, Adobe Illustrator, light burn, draft sight, on-shape, or Laser-web ) of what you need on the surface.

- The second step will be to send its file to the laser engravers machine, by which the controller of the laser engrave machines setup the laser position and is ready to engrave the design on the surface.

- Next, Place the material inside the machine, fix it with a machine fixer and close the machine top.

- Finally, allow the machine to start; the laser begins engraving-process according to the design file. At last, it gives you a decent, sharp, and clean design on the surface.

Possible Materials for laser Engraving

Laser engraved process can be used on various materials depending on the type of laser and optimal laser power.

- Acrylic material

- Glass

- Wood

- Plastics

- Brass

- Leather

- Fabric

- Aluminum

- Wood

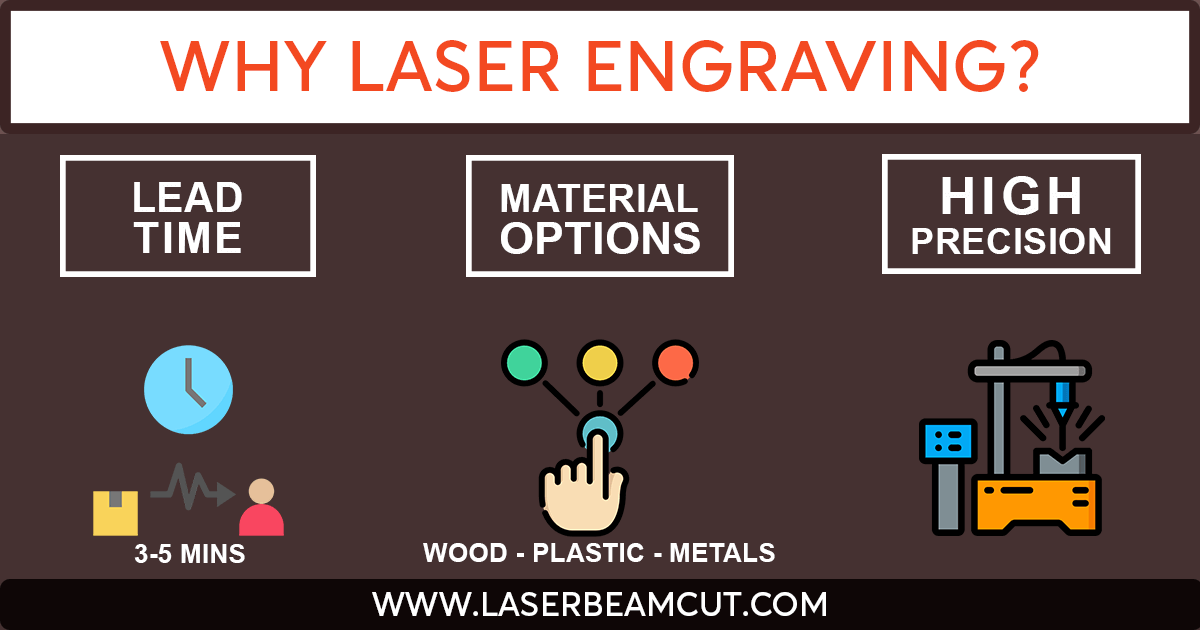

Why Laser Engraving?

As we know, the manual-engravings are time taking process and needs some experts to do this. That’s why laser engraved process are replacing manual engraved process.

Here are some advantages:

Lead Time

Laser engravers machine are a popular process to engrave because of its speed. Every laser pulse vaporizes the material, so it can be done in only a few seconds and still produce a quality result.

Material

Laser engravers can engrave different materials, including wood, plastic, and metal. This flexibility allows you to choose from a variety of materials and designs.

High Precision

Manual laser-engraving is risky and difficult on small, complex materials like jewelry ( rings and necklaces). So by laser-engraving, it all is possible with high accuracy.

Laser Engraver Applications

Laser-engravings are very flexible, so many industries rely on this technology for production. Here we mention some of them.

- Awards or trophies to create a clean-looking engrave-designs on the surface.

- Decorative marking or letterheads

- Barcodes for the production industry

- Jewelry Industry

- Electronic industry

- Medical industry

Laser Engraver Software

The laser engravers need vector files for these process. Some software are listed below that supports laser engravers machine.

- Inkscape – (Free)

- Laser Web – (Free)

- Adobe Illustrator – (Paid)

- Light-Burn – (Paid)

- Draft Sight – (Paid)

- On-shape – (Paid)

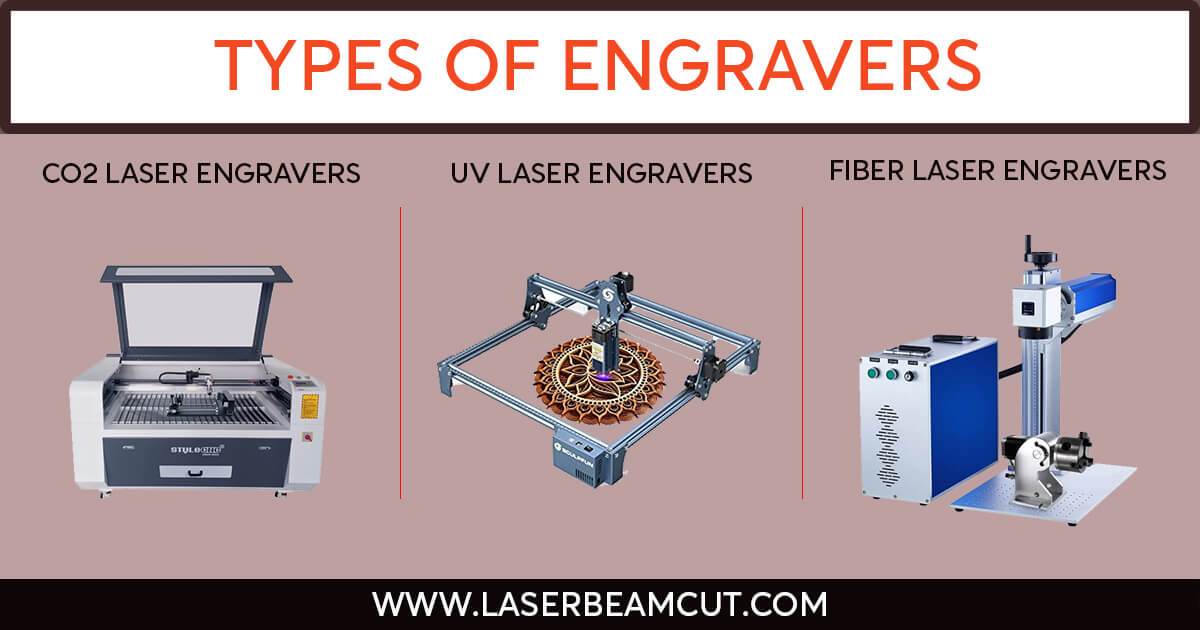

Types of Laser Engraver Machines:

Based on engravings functionality and laser type, engravers machines are of three types

Diode Laser Engraver

Diode laser marking machine adopts ultraviolet laser with a wavelength of 355nm, and the focusing spot is very small for fine marking and engravings. The length of the laser line is about 0.5 mm, which brings convenience for you to mark small patterns on various surfaces effectively Underwater marking also has advantages that are easy to apply to quick-changing patterns.

CO2 Laser Engraver

The laser light produced by a CO2 laser generates; inside a vacuum tube made out of glass, which also contains carbon dioxide. The electrical current causes the gasses to vibrate, which creates light as it aggravates the gasses. The produced light rinses off different mirrors on its way to the lens. Before leaving the laser machine and hitting the material, the lens focuses the beam on one point.

Fiber Laser Engraver

A fiber laser engravers machine are a cost-effective and powerful tool for designers and engineers to create permanent markings in metals, plastics, glass and any other materials on their work surface.

The laser parameters of fiber lasers are also adjustable according to different workpieces and material types. Therefore, it is best for engineers to select the proper settings for their use.

A high-power fiber laser can take deep engravings or rotary carving on various materials by adjusting its power (energy) according to the labeled surface area. In addition to this, with a rotary attachment, users can perform rotary engravings on ring, cups, cylinders, and more.

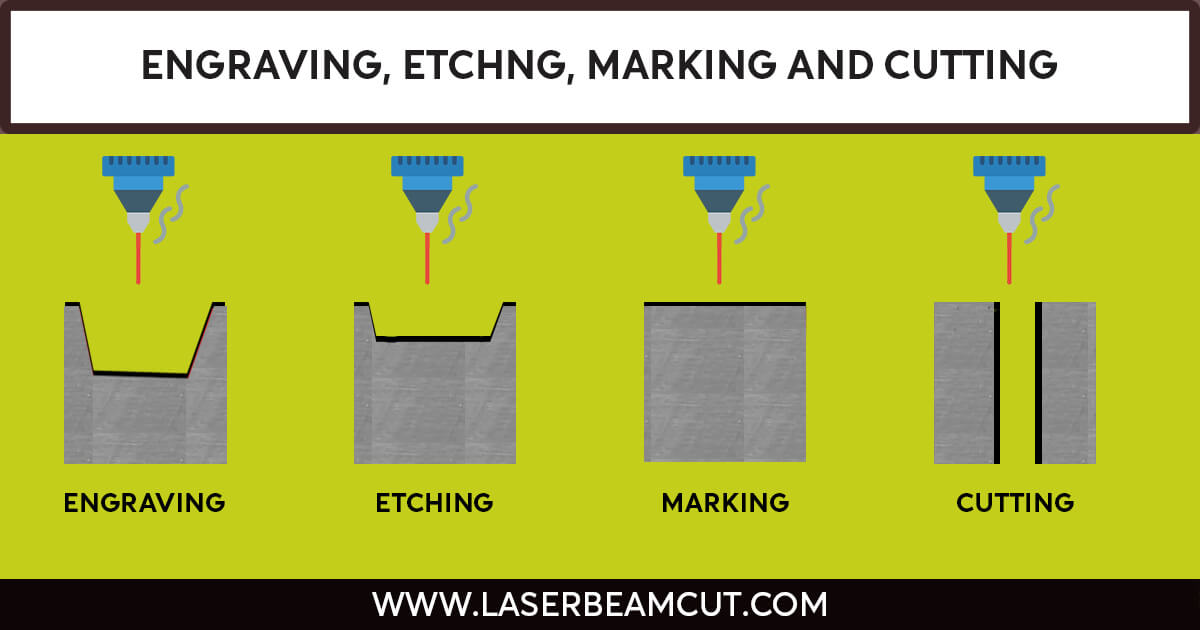

Related terms – Laser Engraving VS Marking VS Etching

At this stage, we are familiar with laser engravings and its processes, but a few of its related terms ( laser engravings, laser cutting, etching, and laser marking ) may puzzle you. Let’s make these concepts clear.

Laser Cutting vs Laser Engraving

The Laser Cutting and Laser Engravings have the same methods but different outcomes due to the laser focal lens.

- Laser cutting (having a longer focal length) is used to cut materials into two parts.

- Laser engravings (having a shorter focal length) only does engrave surface material, depending on the depth we need.

Laser Etching vs Engraving

The Etching involves melting the surface of a material to create the design.

Laser engrave vaporizes the surface of a material to create the design.

Laser Marking vs Engraving

The Laser marking is a process that oxidizes material surface by using a low-power beam and imposing design without removal of material.

To get depth knowledge about these related terms. Laser marking vs etching vs engravings.

Safety Guides about Laser Engraving:

To minimize risks, follow these recommendations when using laser engravings machine:

- Use protective goggles to keep your eyes safe from laser beams.

- A fire extinguisher must keep nearby operators to tackle unexpected fire outbreaks.

- Install a fume-exhaust system to remove pollutants like fumes and smoke.

- Make sure to disconnect power supplies during working inside machines.

Conclusion (Laser Engraving):

Laser engrave is a non-contact process that produces precise, permanent marks. It’s a needy tool for product identification and traceability in several industries.