When we work on any manufacturing project, we need tools depending on the need of the project. But the cutting may be used in every manufacturing process but laser cutting is the one of the best method to cut materials.

So, every technical expert is always concerned with the best tools to adopt for higher-quality results.

In this blog, we will discuss laser cutting in detail. That is one of the best handy tools for cutting purposes. This article will cover the basics of laser cutting, how they works, why you must choose it to over other cutting methods, and discuss the advantages and disadvantages of laser cutters.

Are you ready to learn about this amazing technology? Let’s get started.

What is Laser Cutting?

It is a non-contact process that creates cuts through a material using high-power, focused laser beams on the surface to vaporize or melt the surface.

To create cuts on complex parts no need to design custom cutting tools for different materials.

The Laser cutting is ideal for materials like metals, wood, polymers, and others. It gives precise, repeatability, and smooth finish cuts to any material and these properties of laser cutting make it more valuable for industries to use this technology.

It works on the principle of lasers, and these laser beams are powerful, focused, and monochromatic beams of light. In simple words, in our childhood, we played with mirrors to focus sunlight on paper to burn. The same concept uses in laser cutting.

By using lenses, laser beams are focused on the surface of the material to melt or vaporize it for cutting. To get solid knowledge about lasers and their classes; Click here.

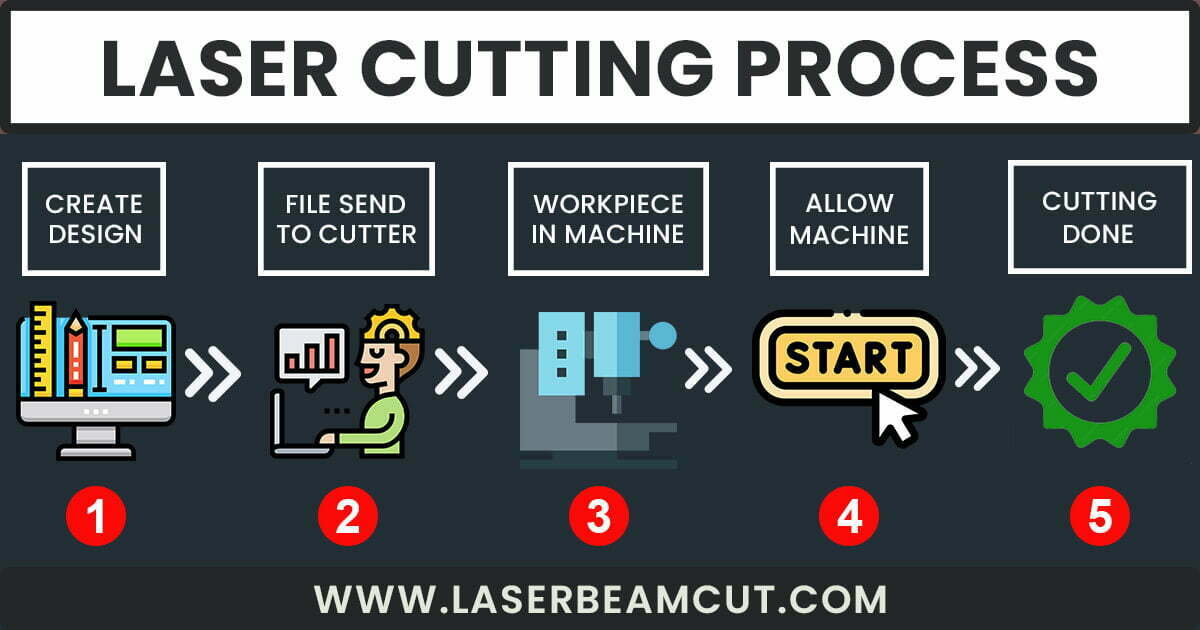

How Do Laser Cutters Work? (step-by-step guide)?

To cut any part by using laser cutting, we use laser cutter machines to cut materials. Here is a simple step-by-step overview of the laser-cutting process.

- Make a design on computer software that needs.

- Place the workpiece on the machine bed and fix it with any clamp. Make sure that the workpiece position is straight.

- Send design file from pc to laser cutter machine

- Set the power of the laser depending on the material type and thickness.

- Allow starting process

- Finally, the machine cuts the material according to the design

These are simple steps by which it perform. But the question remains, how does it work?

When a powerful, focused beam hits the material surface, its temperature increases and the cutting process begins.

It can end by melting the material or directly vaporizing it, depending on the type of material. In short, we can call it a thermal separation method.

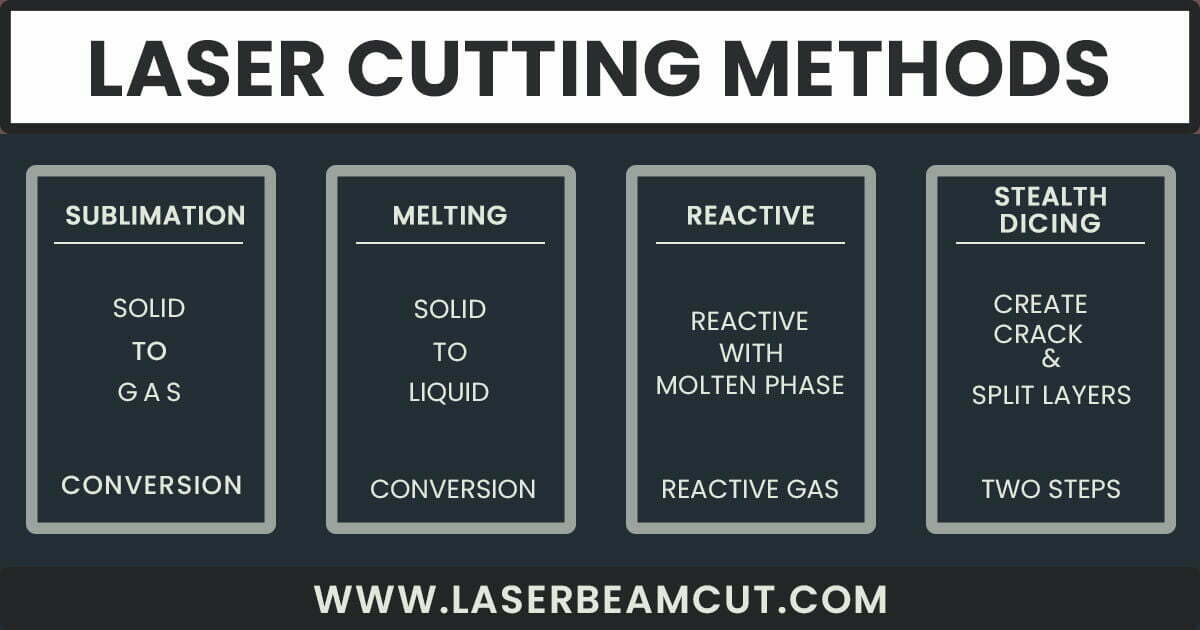

Laser Cutting Methods

There are four ways to cut materials with laser cutters. We can choose one of laser cutting methods according to our material specifications and need.

- Sublimation cutting

- Melting Cutting

- Reactive Cutting

- Stealth Dicing

Sublimation Cutting

It is a process by which cutting material suddenly changes its state from solid to gaseous stage by using high-power cutters to cut materials. It is also called vaporization cutting.

Sublimation laser cutters help you to cut through a material without melting its surface.

In this process, additional material would remove from than actual design, that called kerf laser cut. It is due to the width of a laser beam. It should consider during design calculations.

As it requires powerful laser cutters and kerf factors to do sublimate cuts, it is best for materials like plastics, paper, and boards that need less power than metals.

Fusion or Melt and Blow Cutting

It is a process by which cutting material melts to cut. It requires less power laser than the sublimation process.

During this process, beams raise the temperature of the material surface till it starts melting, and cutting begins. This stage needs to remove this melting part from the surface; coaxial gas jets use for this purpose. These jets contain gases that are inert or non-reactive.

Stainless steel, titanium, and aluminum alloys can be cut by this method as these are non-oxidizing metals.

Reactive Cutting or Flame Cutting

It is a process by which cutting material melts by a laser beam at the start, and then reactive gas is used to react with this molten material to make it faster and use less energy.

In this process, coaxial gas jets force the cut material out of the surface.

It makes a low-quality cut that melting cut process. Carbon and Titanium steel can cuts by this process.

Stealth Dicing

It is a new technology of cutting by which no kerf laser cut produces and gives high quality and clean cut.

The stealth dicing process takes two steps.

- The first step is to create a crack in materials internally by focusing a laser beam that permeates through materials. The layer which produces fracture through this process is called the wafer layer, stealth dicing layer, or SD layer.

- The second step is to split this SD layer or wafer layer by applying external stress to cut.

Laser Cutters Types

Based on laser type of laser cutters, has three types.

CO2 laser cutters:

These types of laser cutters are low-power, relatively inexpensive laser cutters. They operate by the electric source to stimulate CO2 molecules in the laser gain medium. For cutting, engraving, and boring operations, the CO2 Laser Cutters are the best choice.

Wood, cardboard, leather, acrylic, glass, plastics, and many more materials are possible for laser cutting.

Fiber Laser cutters:

These are high-power laser cutters than CO2 type. These laser cutters use fiberglass as a gain medium of a laser.

Metals and non-metals cuttings are possible by fiber laser cutters.

Neodymium laser cutters:

These are also high-power laser cutters and use for thick metals for cutting purposes.

To get depth knowledge about lasers and their types, read this blog.

Laser Cutting Materials

Some material cutting is possible with laser cutting but some material cutting is not possible. Listed below are the types of possible materials that you can cut with laser cutters.

Metal

Metal cutting is one of the best applications of laser cutters. Its use is almost in all industries for manufacturing processes.

For metal, a clean cut and smooth finish are possible with laser cutters.

A laser cutter can cut metals like stainless steel, mild steel, tungsten, nickel, brass, and aluminum.

Wood

Laser cutters of wood cutting are the best option for complex parts because they can provide high precision in thin wood sheets.

Never Cut These Materials

Never cut these materials that listed below.

PVC or Artificial Leather

When we cut such types of materials, it emits chlorine gas which is dangerous. So recommendation is to not cut these materials.

Polystyrene Foam or Plastics

These materials can catch fire due to high power beams, so these materials cutting are also not recommended.

Laser Cutter Software

The following design software needs for laser-cutting purposes.

- To create 2D designs: adobe illustrator, Inkscape, or AutoCAD software is the best choice.

- To create 3D designs: Solid Works, Pro-e, and Catia software

Advantages of Laser Cutting

Laser cutters offers many advantages over other processes, such as

- It’s easier to handle and reduces the risk of contamination.

- It is ideal for cutting complex designs into smaller parts while leaving metal free of burrs and with a clean cut.

- Precise cuts

- Variety of materials possible

- Reliable

- Speed processing

Disadvantages of Laser Cutting

It has also disadvantages like

- High power consumptions

- Not easy for thick metals sheets

- Cut edges may burn

- From plastic like materials, toxic emission may release

Difference between Laser Cutting, Engraving, Marking and Etching

To get brief knowledge about these related terms of Cutting, Marking , Engraving, and Etching. Read this blog.

FAQs ( Friendly Asked Questions ):

1. Which is best for our task? Laser Cutting vs Plasma Cutting

Ans: It depends on your need and material type. If you need high-quality and precise cuts, should go with laser cutting. If the material thickness is large, go with plasma cutting.

2. Why is aluminum cut more difficult to laser than mild steel cut?

Ans: Laser cut aluminum is more arduous than laser cut stainless steel because aluminum is softer than stainless steel.

3. Can we cut any material by laser cutting machines?

Ans: In simple words, it’s not possible. It depends on the material type. Some materials can catch fire so should read the instructions before using them.

4. Can Laser Cut Stones?

Ans: It is possible but not recommended due to two reasons.

- Need high-power laser cutters

- It is possible in layers and time taking process

5. which file formats are used for laser cutter machines?

Ans: Vector files (Ai, SVG), Raster files (JPEG, TIFF), and some CAD design files are used for laser cutting processes. Windows Bitmap (BMP) file is used for laser cutter machines.