You can use different materials to make unique products by cutting them into different shapes. Laser Cutting is one way to cut these materials. But there are some limitations in laser cutting material.

When cutting certain materials, it needs to know whether a laser cutter is safe for the material or not. Stay with us to get in-depth knowledge about the material possibilities of laser cutting.

Lasers parameters like power, speed, number of passes, and others play a significant role in laser-cutting materials. By selecting the optimal laser parameter, we can achieve high-quality results. In this blog, We will also discuss these parameters.

In the end, I will discuss materials that are not suitable for laser cutting. Are you interested in learning more? Let’s get started.

How do Laser Cutting Materials work?

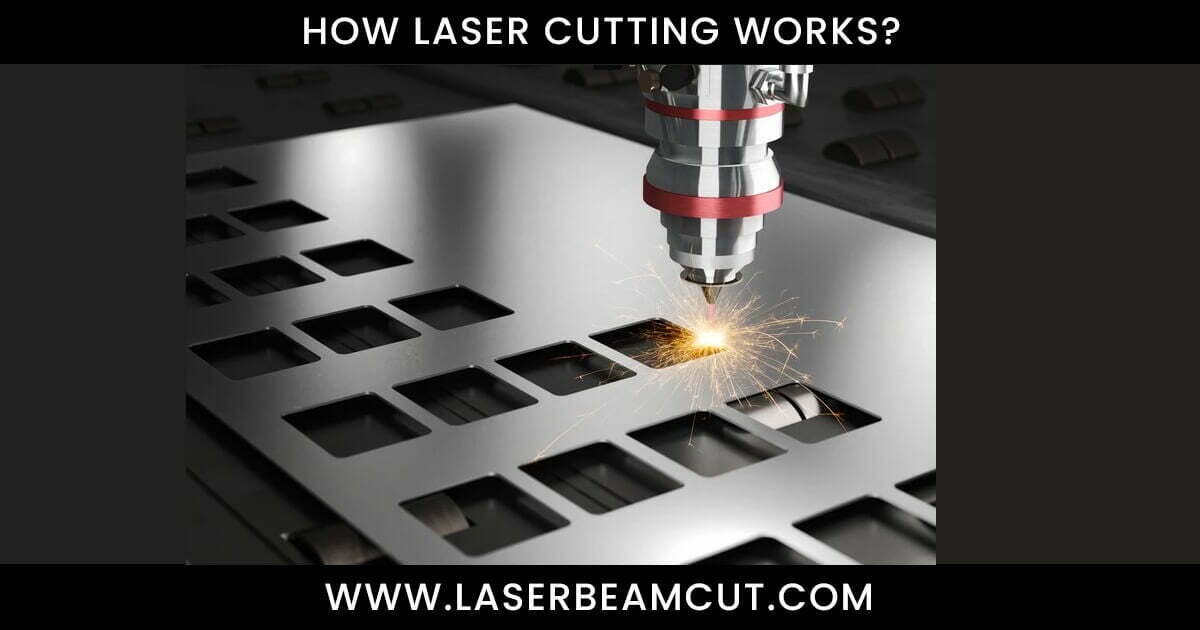

The laser cutters cut materials by focusing a high-power laser beam on the material surface to vaporize it to achieve the desired design cuts.

Cutter machines use different kinds of lasers to cut materials, so to cut distinct materials, you need to choose a specific laser cutter machine.

CO2, diode, and fiber lasers use for laser cutting applications.

CO2 laser cutters use to cut non-metals. However, high-power CO2 lasers can cut metals too. Their wavelength range is near 10600 nm.

Fiber lasers are ideal for metal cutting. Their wavelength range is near 1060 nm.

Diode lasers can cut both metals and non-metals. These are low-power lasers with a wavelength range from 450 nm to 950 nm.

What Materials Can a Laser Cut?

Lasers can cut every material type: but some materials produce harmful noxious fumes. Due to this, everyone should know about their possible materials before going into practical work.

Lasers are safe on materials like wood, paper, and metals.

But materials like stones, ABS plastics, and Vinyl PVC are not recommended.

Possible materials for Laser cutting

Natural materials like wood, paper, leather, and metals produce no harmful by-products by laser cutting.

Laser Cutting for Wood

Wood is the most popular material for laser cutting applications. It produces smooth, charred edges that can remove by sanding.

There are generally two classes of woods: Softwoods and hardwoods. Each class has specific properties and upon these factors selection of laser cutters depends.

Hardwood Properties | Softwood Properties |

Dark color | Light color |

Heavy | Light in weight |

Expensive | Less expensive |

| Have long lifetime | Have shorter lifetime |

| Strong to resist by environment | Changes in properties over environment changes |

For Industrial level projects, 150-watt CO2 Laser Cutter machines mostly use cut up to ¾ inches thick wooden workpieces at high speed.

For domestic-level projects, a 50-watt CO2 laser cutter commonly uses to cut 0.25 inches-thick wooden pieces.

Wood Lasers Cutter machine can cut wood as well as it can engrave wood with high-contrast designs.

These machines need less power for wood engraving. A 10-watt diode laser cutter is ideal if you want to engrave a custom design on wood.

However, heavy smoke produces by the wood lasers-cutting process. So its recommendation is to install an exhaust system that disposes of smoke from the work area.

| Wood Type | Wood Name | Behavior |

| Hard Wood | Cherry, Walnut, Oak | Ideal for high-contrast engraving but are not easy to cut by lasers |

| Soft Wood | Balsa, Alder, and Pine | Can easily cut and possibly low-contrast engrave designs |

| Plywood | Lumber core, Veneer core | It is easy to cut with the lasers. But it can produce harmful fumes. |

| MDF wood | Medium Density Fiberboard | Cutting and engraving are possible: but they can produce harmful fumes |

Laser Cutting for Plastics and Acrylic

By cutting plastics and acrylic materials, we can create some amazing pieces of art. We can create signs, logos, wall art designs, and much more.

But some laser-cutting plastics release harmful fumes during the process, so you should use an exhaust system to purify fumes before releasing them into the atmosphere.

Some plastic materials that are best for lasers cutting are listed below:

| Plastic Name | Cutting Behavior | Engraving / Marking Behavior | Safety |

| Acrylic | Excellent | Good | No Harmful Fumes |

| Fluoropolymers | Good | Good | No Harmful Fumes |

| Delrin | Good | Acceptable | Can catch fire and harmful fumes produce |

| Mylar | Good | Acceptable | No Harmful Fumes |

| Polycarbonate | Poor | Good | Heavy smoke produces |

| Polyimide | Poor | Good | No Harmful Fumes |

Acrylic Plastics are ideal for laser cutting, engraving, and marking operations. It produces a smooth surface finish.

The C02 laser cutters of 40-watt power rating machines are best for cutting plastic and acrylic materials.

Plastics of different types behave differently under lasering operation. Some produce Flame-Polished edges, some toxic fumes, and some can catch fire.

Other plastic materials need good process controls to avoid harmful fumes and excessive heat from the surface.

To achieve this, use high-power lasers with small spot-size beams, fast cutting speeds, and an air assist system to minimize fumes and heat from the surface.

Laser Cutting Metals

Laser cutters need high-power lasers to cut metals that can produce enough heat to melt or vaporize them.

Some metals have highly reflective surfaces, so protective surfaces coated on these metals absorb laser beams instead of reflecting them.

CO2, fiber, and direct diode lasers (DDL) can cut metal sheets to create unique and valuable parts.

CO2 cutters can cut thick metals well, while fiber cutters can cut thin metal sheets.

Diode lasers are low-power laser cutters. Due to this, fine cuts can produce by these cutters.

Metal materials can also produce harmful fumes, so need exhaust systems to keep safe the work area.

Laser Cutting Paper

Lasers machines can easily cut paper. But these materials are highly flammable and can catch fire during operations.

To avoid this hazard, do optimal parameter settings of machines as per paper type.

A diode laser cutter (10 watts) of low power is used to cut paper materials.

You can create attractive gifts with paper cutting for your beloved ones.

Laser Cutting Leather

Leather materials are famous in the fashion industry for making unique and modern designed products. Lasers cutting is ideal for making leather cuts as per design.

Leather cuts are safe by these processes except leathers that contain vinyl, as they release harmful toxic fumes.

Lasers cutters of 40-watt machines with low pressure are ideal for cutting leather.

By leather cutting: you can create wallets, belts, backpacks, and much more.

Laser cutting Fabric

Lasers are a great way to cut fabric materials and other textiles. The heat from the laser melts or burns through the material, leaving a sharp edge that will allow you to make a design or cut out pattern pieces.

Laser cutting Glass

It is a brittle material. So cutting by laser cutter machines is difficult.

Some glass is possible to cut by using high-energy lasers. It works best with thin glass (when using specialized cooling processes).

Stained glass is possible to cut at high wattage (400 W).

Never Cut These Materials

The most dangerous aspect of laser cutting is that it can cause fires and releases toxic fumes. Be careful not to use materials that are flammable or melt fast.

| Material | Reason |

| ABS | Release harmful cyanide gas. 3D print possible but not recommended by lasers machine |

| Vinyl / PVC | Emit chlorine gas which affects machine metal with corrosion |

| Oily Wood | Risk of catching fire |

| Foam | Melts quickly and catches fire |

| Fiber Glass | Release toxic fumes |

| Carbon Coating | Can not cut |

| Stone | Very High-power laser cutters require for cutting stones. |

| Highly Reflective Metals | These metals reflect the laser beam. |

Crucial Laser Parameters setting for Cutting Materials

Getting the desired cut on any material by laser cutter machines is possible with appropriate machine parameters settings. These parameters are power, frequency, speed, and other parameters.

Changing the settings on a single parameter may affect the cutting results, so be careful before doing this.

Each material needs specific settings of machine parameters. So to get the best setting parameters of machines for any material, try each parameter on a small piece of your workpiece. A point where it gives the best results, note these settings and apply them in the future.

Best Laser Cutter

We have a lot of laser cutters in the market, but I will discuss a few famous, and those machines that are possible for all materials cutting.

ORTUR Laser Master

These machines have four variants ORTUR 2 Pro S2-LU2-2, ORTUR 2 Pro S2-LF, ORTUR 2 Pro-S2-SF, ORTUR 2 Pro S2-LU2-10A, ORTUR Laser Master 3. Each variant has limitations, but from these, the ORTUR Laser Master 3 is the best machine.

This machine can engrave, etch, or cut material surfaces. As these machines have low-power lasers, they can cut only soft materials.

The Ortur laser Master machines have the following specifications:

Machine Parameter | Detail |

Power | 1600 milli-watt – 10 watt |

Wavelength | 450 – 455 nm |

Machine Size | 641*625*150mm |

| Laser Spot | 0.07*0.06mm – 0.05*0.1mm |

| Speed | 10000mm/min – 20000mm/min |

| Working Area | 15.75 * 15.75 inches |

OMTech Laser Cutter

These are powerful laser cutter machines, and they can cut hard materials. These machines are best for small businesses or industrial use.

These machines have a power range of 60 – 150 watts. For small businesses and hobbyists, a 60-watt OMTech cutter is best. These machines use light burn software and are compatible with Windows, Mac, and Linux operating systems.

The OMTech machines have the following parameters:

Machine Parameter | Detail |

Power | 60-watt – 150 watt |

Machine Size | 47.2×34.3×36.6 inch – 86.6×60.6×37 in. |

| Cutting / Engraving | 0-0.2″(depending on materials) |

| Working Area | 20×28 inch – 40×63 inch |

xTool D1 Pro 20 Watt Laser Cutter

These cutters use diode lasers and are low-power Cutters, which are ideal for situations where fine cuts have priority over time. This machine has 0.01 mm motion precision.

The xTool D1 Pro 20-Watt cutter has the following specifications:

Machine Parameter | Detail |

Power | 20 watt |

Laser Type | Diode |

| Speed | 400 mm / s |

| Working Area | 430 * 390 mm |

Final Thoughts

Laser cutters can cut different materials to create unique and valuable products. Some materials are safe to cut with these cutters, and some are unsafe and produce harmful fumes. So be aware of their behaviors before start working on such materials.

FAQ – Friendly Asked Questions:

1. Why should you find Optimal Settings?

Using optimal settings for each material gives a smooth and clean cut.

If we do not operate materials on their optimal parameters settings, they may get fired or give sharp edges.

2. Which lasers-type cutter machine is best for material cutting?

CO2 and diode laser cutters are best for various material-cutting applications.

3. Can we cut stones with a laser cutter?

Yes, stone cutting is possible by laser cutter machines. However, it is not a good way to do so.

A very High-power laser cutter requires for cutting stones, which means a waste of energy.

4. How much power of the machine needs to cut fabric material?

For most fabrics, the recommended laser power is 100W. If cut on a thicker fabric piece, composite fabric material, or leather: best to use a higher power setting, like 130 or 150W.

5. Can all materials possibly be cut with laser cutters?

All materials cutting is possible by laser cutter machines. But few materials are unsafe by laser cutters that produce chlorine gas: such as vinyl and PVC materials.