Introduce your laser with precision! Are you fed up of dealing with inaccurate engravings, wasting materials, or costly errors? The issue could be with the bed of your laser.

We are introducing the Honeycomb Laser Bed, an innovative solution that allows you to actually achieve exact and constant outcomes. Its unique design provides a stable surface for your laser machine.

Make sure you are ready to revolutionize your workflow and gain unbeatable accuracy with Honeycomb Laser Bed. Honeycomb Laser Bed!

Understanding the Structure Of Honeycomb Laser Bed

Honeycomb Laser Bed Honeycomb Laser Bed is constructed with a unique design that guarantees optimal performance and accuracy. The bed is comprised of:

The bed is composed of:

Honeycomb Pattern:

A set of hexagonal cells interconnected to bring a level and solid surface for your laser.

Aluminum Construction

A durable, lightweight aluminum material that gives you the strongest strength with minimal warping.

Precision-Crafted Cells

Each cell is carefully designed to assure accuracy and consistency in Laser cutting and engraving and marking.

Optimized Cell Size

The honeycomb cells are specially made to be able to handle various sizes of laser beams, which ensures maximum performance.

Smooth Surface Finish

A polished finish on the surface ensures easy movement and little resistance to lasers during operations.

This structure allows to allow the Honeycomb Laser Bed

- Eliminate material waste and errors

- Increase precision and ensure the consistency

- Laser operations at high speed.

- Create a long-lasting and durable surface

Top Pick Honeycomb Laser Bed for Your Engraver

Here are a selection examples of desirable Honeycomb Beds on the market, with their specifications and features:

- Makeblock xTool Honeycomb Bed

- JICCODA Honeycomb Cutting Table (17.32×17.32×0.87 inch)

- JICCODA Honeycomb Cutting Table (19.7×19.7×0.87 inch)

- SCULPFUN Honeycomb Table

- Comgrow Honeycomb Cutting Table

Makeblock xTool Honeycomb Working Table

Get acquainted with you at the Makeblock xTool Honeycomb Working Table – the ideal companion to your laser equipment! This unique and flexible table is built with honeycombs which ensures optimal airflow and precision engraving or laser cutting payoff.

Enhance your workflow with this essential accessory to improve performance and efficacy. Make yourself ready to raise your machine’s laser capabilities to brand new levels with this Makeblock xTool Honeycomb Working Table!

Key Features of xTool Working Table

| Feature | Value |

|---|---|

| Compatibility | xTool D1, D1 Pro, and most laser engravers |

| Working Area | 19.68″ x 19.68″ x 0.87″ (500 x 500 x 22 mm) |

| Heat Dissipation | Fast and efficient |

| Material | Iron and aluminum |

| Protection | Dual protection for materials and desktop |

| Smoke Evacuation | Honeycomb design for better ventilation |

| Durability | Stable, durable, and rust-resistant |

| Measurement Graduations | Precise graduations on the honeycomb plate |

| Wide Compatibility | Dioxygen, fiber, CO2, and more laser engraving machines |

JICCODA 15.7×15.7×0.87 inch Honeycomb Working Panel

Take a look at The JICCODA 15.7×15.7×0.87 honeycomb working panel! A honeycomb panel designed specifically to work with lasers provides excellent support and airflow for engraving and laser cutting.

Enjoy precise and reliable payoff using this sturdy and well-sized accessory perfect for increasing your laser’s performance. Enhance your workflow today by purchasing this JICCODA Honeycomb Panel for Working!

Key Features of JICCODA 15.7×15.7×0.87 inch Working Table

| Key Features | Values |

|---|---|

| Fast Heat Dissipation | Facilitates efficient smoke exhaustion, prevents material blackening, better engraving |

| Double Desktop Protection | Includes metal aluminum panel for extra protection, corner protectors for added safety |

| Large Size & Quick Measurement | Dimensions: 15.7×15.7×0.87 inches, precise graduations |

| Durable Materials | Made of iron and aluminum, high-precision CNC processing, strong, stable, and rust-proof |

| Wide Compatibility | Suitable for Ortur engraving machines, compatible with other laser engraving machines |

Find this JICCODA 19.7×19.7×0.87 inch Work Table The perfect partner to your laser equipment! With its compact but spacious layout, this table gives an extremely solid surface that is ideal for the cutting of lasers or engraving.

With its sturdy construction and optimal dimensions, it’s now the time to take your laser-related job to a new level using JICCODA!

Key Features of JICCODA 19.7×19.7×0.87 inch Working Table

| Key Features | Values |

|---|---|

| Product Name | JICCODA Laser Cutter Honeycomb Working Panel Set, 19.7×19.7×0.87 inch |

| Material | High-quality aluminum alloy and metal materials |

| Double Protection | Honeycomb panel and aluminum panel provide dual protection for your desktop |

| Accurate Scale Lines | Right-angle measurement scales on X and Y axes for easy and quick measurement of cut objects |

| Wide Compatibility | Compatible with various laser engraving machines, including diode DIY CNC laser engraving machine and CO2 laser |

| Easy to Install and Use | Convenient installation and user-friendly operation |

| Size | 19.7×19.7×0.87 inch (suitable for specific laser engraving machine models) |

| Rust-proof | Resistant to rust and corrosion |

| Versatile and Reliable | Provides reliable performance with different laser engraving machines |

SCULPFUN Honeycomb Working Table

SCULPFUN Honeycomb working Table The ultimate Laser machine accessories. This table’s innovative design provides the best assistance and airflow to assure precision laser cutting as well as engraving.

Enhance your workspace by acquiring SCULPFUN’s SCULPFUN Honeycomb Working Table and discover endless possibilities for laser-based projects.

Key Features of SCULPFUN Honeycomb Working Table

| Product Name | SCULPFUN Honeycomb Working Table 300x200x22mm |

|---|---|

| Product Type | Laser Cutting Honeycomb Laser Bed |

| Compatibility | CO2 or Diode Laser Engraver and Cutting Machine |

| Product Description | Laser Engraver Accessories, Smooth Edge Cutting |

| Features | |

| Better Laser Engraving Experience | Open structure honeycomb hole design for optimal airflow and effective smoke exhaust, preventing material darkening or warping due to smoke. |

| Cutting Through Observable Design | Metal plate at the bottom emits bright light when cutting through wood or acrylic, ensuring precise judgment of cutting completion. No need to calculate the number of cuts. |

| All-metal High Flatness | Solid, deform-resistant structure made of high-precision CNC processed metal, with excellent flatness. |

| Desktop Protection Board | Equipped with a metal desktop protection board to safeguard against laser damage. Compatible with various diode laser engravers. |

| Square Measuring Ruler | X-axis and Y-axis contain precise scale lines for quick measurement of cutting objects. |

| Wide Compatibility | Compatible with various diode DIY laser engraving machines and CO2 laser engraving machines. |

| Dimensions | 300mm x 200mm x 22mm |

Comgrow Honeycomb Laser Bed

Get acquainted with you at the Comgrow Honeycomb Laser Bed – the perfect solution for laser enthusiasts. With the best flow and stability, this revolutionary accessory can improve the laser’s cutting capabilities and payoff.

Discover the full potential of your machine by using Comgrow Honeycomb Laser Bed. Comgrow Honeycomb Laser Bed and enjoy the highest quality and efficiency as never before.

Key Features of Comgrow Honeycomb Laser Bed

| Key Features | Values |

|---|---|

| Honeycomb Work Area Size | 15.75 x 15.75 inches (400×400 mm) |

| External Bezel Size | 17.71 x 17.71 inches (450 x 450 mm) |

| Aperture Size | 7.5 mm |

| Material | Iron and Aluminum |

| Heat Dissipation | Fast and efficient |

| Rust-proof | Yes |

| Smoke Emission | Accelerated through uniform honeycomb holes design |

| Protection | Sturdy frame for the honeycomb work bed, aluminum panel for desk protection, corner protectors included |

| Compatibility | Comgrow Z1 laser engraving machines, diode fiber, CO2 laser engraver machine |

| After-sales Guarantee and Support | Exhaustive after-sales service with easy access to Comgrow brand page and team support |

How to Choose the Right Honeycomb Bed for Your Laser Machine

When deciding on the ideal Laser Cutting Bed for your laser machine, you should consider the following aspects:

Compatibility

Check that you have a bed that is appropriate for the laser’s model.

Size

Pick a bed that fits the dimensions of the laser machine as well as the size of the piece you’ll be together.

You should consider purchasing the Laser Engraving Bed, a minimum size of 400×400 mm. Beds smaller than this can take many time for those working on different large objects.

Material

The bed’s material can impact its performance and durability. Iron, stainless steel, along with aluminum are the most commonly used materials for Honeycomb Laser Beds.

Extension

Think about whether you’ll need an extension to be able to handle larger parts.

Price

Laser Engraving Bed can range in cost, so take into consideration your budget as well as the value that the bed can provide to your laser operation.

Maintenance Tips for Laser Honeycomb Beds

Ensuring the longevity and efficiency of the Honeycomb Laser Bed demands constant maintenance and attentiveness.

To warrant that you properly keep the health of your Honeycomb Cutting Bed, consider the following suggestions:

Maintain cleanliness

Remove any debris or leftovers from laser processes by gently rubbing or smoothing all over the area on your Laser Work Bed with a soft cloth. Beware of harsh cleaners that could cause damage to your laser.

Avoid excessive heat

Honeycomb’s structure offers effective heat dissipation. However, the excessive heat may cause damage over the course of time. Beware of exposure to direct heat sources. Honeycomb Bed to sources of direct heat, or long exposure to temperatures that are too high.

Check for damage

Examine the Laser Work Bed for any indications of wear or damage such as dents scratches or warping. If you find any signs of issues, you should upgrade the bed in order to assure the excellent performance.

Use Protective Materials

When working with sensitive or delicate workpieces, make use of the appropriate materials, such as tape or paper to avoid any damage to the surface of your bed.

Lubricate Parts Regularly

Make sure that the Laser Work Bed by regularly Lubricating all moving parts including the sliding rails. Apply a silicone-based lubricant in order to warrant the accurate performance and to prevent wear.

The Impact of Honeycomb Bed Design on Laser Cutting Quality

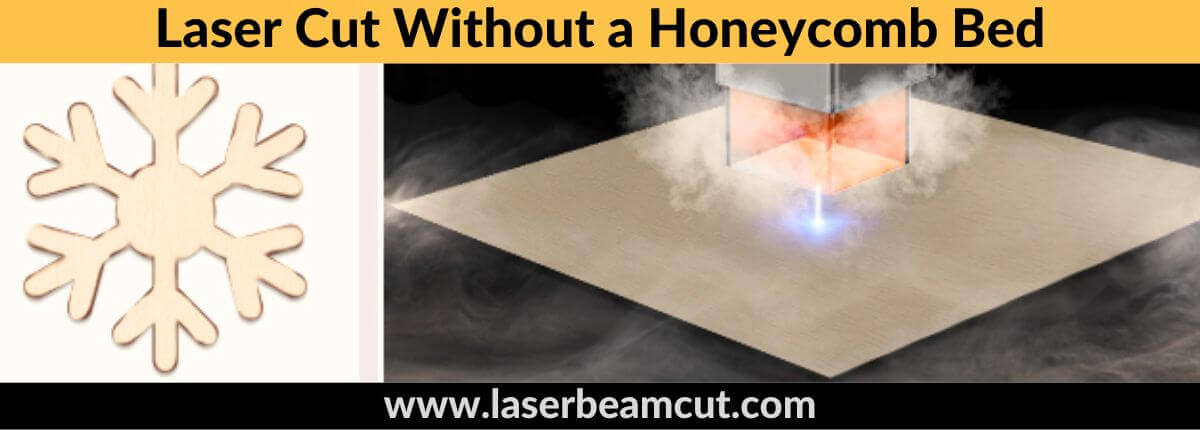

A Laser Work Bed is an important element in ensuring top-quality laser cuts. A bed that is not adequate for the machine could result in damage to the workpiece, or irregular cuts.

Here are a few photos to show the effect from Honeycomb Bed design on laser cut quality:

Laser cut without a Honeycomb Bed

Laser cut with a Honeycomb Bed

You can clearly see that Honeycomb Bed Technology provides the needed support and stability to the workpiece. This allows for clean and precise laser cuts.

Designing a Custom Laser Honeycomb Bed for Your Laser Machine

Designing a custom Laser Bed System for your laser machine can improve the efficiency and quality of your laser operations.

Here are some steps to guide you in designing your own custom Honeycomb Laser Bed:

Determining the Required Dimensions

Find the bed’s size on your laser and then determine the necessary dimensions for your customized Laser Workbed. Consider the maximum dimensions of the workpieces that you’ll be working with, and add the extra centimeters to allow for safety margins.

Select the material

Choose the proper material for your customized Laser bed system. The most commonly used materials for a Laser Work Bed include aluminum, stainless steel and titanium. Take into consideration the weight and durability as well as the heat resistance of each one.

Decide on the Cell Size and Thickness

The thickness and size of the Honeycomb Cutting Bed can affect the quality of the laser cut. The thinner and smaller cells give better support to fragile workpieces and reduce the possibility of surface damage.

Determine Cell Shape

The design of the cells inside the Honeycomb Cutting Bed will also affect the quality of laser cuts. Cell shapes that are common include hexagonal or square and round. Pick a cell shape that is appropriate for your laser cutting requirements.

Create extensions (Optional)

You can rise the flexibility of your customized Laser Workbed by adding extensions. They enable you to accommodate larger workpieces, or several smaller pieces at once.

Look for competent assistance

If you’re unsure of the design of your customized Honeycomb Bed Technology, seek competent advice from a certified producer or engineer to assure an optimal quality and design.

Conclusion

In the end this, The Honeycomb Laser Bed series offers an array of cutting-edge solutions for laser cutting and laser engraving applications.

With their distinctive honeycomb design and top-quality aluminum construction, these products offer the safety, efficiency and accurate working surface for a variety of tasks.

Enhance the quality of your engraving by purchasing honeycomb laser beds. Honeycomb Laser Bed series today!