If you’re exhausted by the traditional and often imprecise fabric-cutting methods, consider investing in a fabric laser cutting machine.

The fabric cutters come with CO2 and Fiber lasers. These machines give precise and quality cut results.

This article delves into the world of these machines, covering their definition, functionality, advantages, and crucial factors to consider before buying one.

What is a Fabric Laser Cutter?

A fabric laser cutting machine is a piece of equipment that uses laser technology to cut fabric into specific shapes and sizes.

It is a computer-controlled machine that uses a high-powered laser beam to cut through the fabric with extreme precision. The fabric laser-cutting machine focuses the laser beam on a specific area of the fabric material, causing it to heat up and vaporize, resulting in a precise and neat cut.

Types of Fabric Laser Cutting Machines

There are two main types of fabric laser-cutting machines:

- CO2 laser cutting machines

- Fiber laser cutting machines

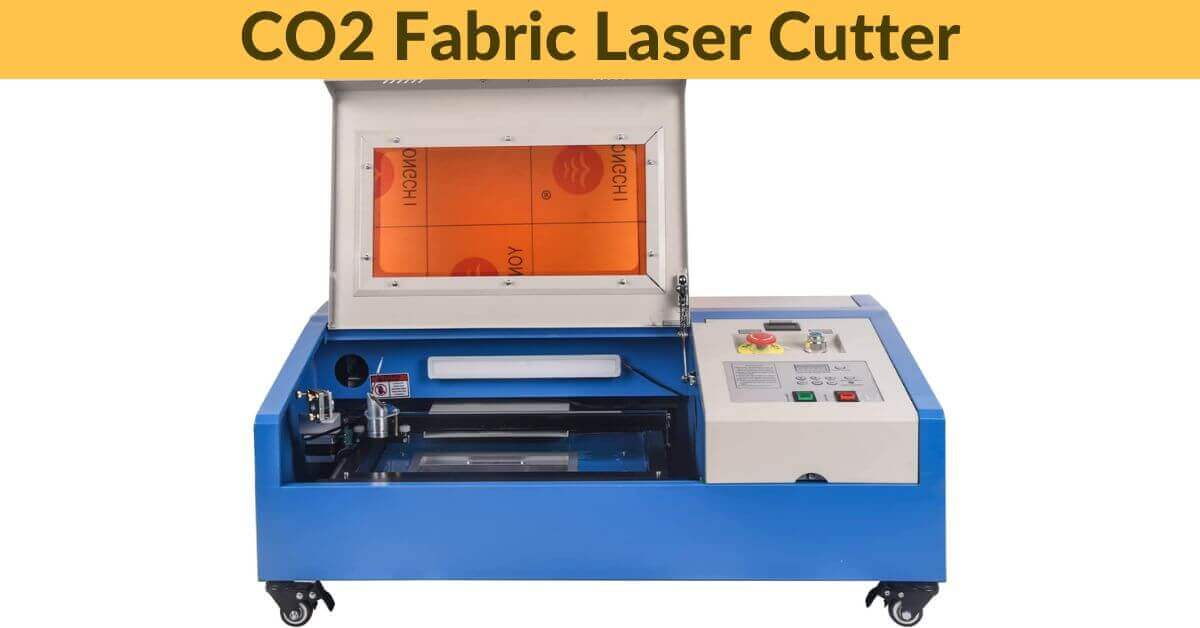

CO2 laser cutting machines

A CO2 laser cutting machine is a cutting tool type that uses a lazer beam to cut through materials. To generate the lazer beam, the fabric laser-cutting machine directs a gas mixture of carbon dioxide, nitrogen, and helium onto the fabric, textile, material, or substrate. The lazer beam heats the material to the point where it melts or vaporizes, leaving a clean and precise cut.

These machines are suitable for cutting various materials, including wood, plastic, and fabric. They are relatively inexpensive and can cut through thick fabrics quickly.

Fiber laser cutting machines

To cut fabrics, fiber laser cutting machines use a high-powered laser beam. The fabric laser-cutting machine generates the laser beam; by using a series of lenses and mirrors that focus the lazer energy onto a minor point, resulting in a high-intensity beam of light.

These machines are more suitable for cutting thin fabrics and are more expensive than CO2 lasar cutting machines.

Benefits of a Fabric Laser Cutting Machine

There are numerous benefits to using a fabric laser-cutting machine, including

- High accuracy and precision in fabric cutting

- Fast cutting speed, leading to increased production output

- Versatility in cutting a wide range of fabric types and thicknesses

- Minimal waste production, making them environmentally friendly

- Flexibility in cutting intricate designs and shapes

- Reduced need for manual labor and less chance of human error

- Improved efficiency and cost-effectiveness in fabric-cutting processes

Factors to Consider when Buying a Fabric Laser Cutting Machine

Before purchasing a fabric laser cutting machine, there are several factors to consider, including:

Price

The price of fabric laser-cutting machines can vary greatly, depending on the type and features. It ranges between a few hundred dollars to thousands of dollars.

Size

Consider the size of the machine and your workspace. You should ensure that the fabric laser cutter you choose fits comfortably in your workspace, as these machines come in various sizes.

Cutting area

The cutting area refers to the size of the fabric that the machine can cut. Consider the size of the fabric material you typically work with and ensure that the machine’s cutting area can accommodate it.

Cutting speed

When we talk about cutting speed in fabric lazer cutting machines, we refer to the machine’s ability to cut through the fabric quickly. Consider the machine cutting speed and ensure that it meets your needs.

Maintenance

Consider the maintenance requirements of the machine and whether you have the resources to maintain it. Fabric laser-cutting machines require regular cleaning, calibration, and maintenance to ensure proper functionality.

Maintenance and Safety Tips for a Fabric Laser Cutting Machine

To ensure the longevity of your fabric lazer cutting machine and your safety, follow these maintenance and safety tips:

Maintenance Tips:

- Regularly clean and inspect the machine for any signs of wear or damage

- Keep the lens and mirrors clean and free from debris to ensure optimal performance

- Check and replace the cutting head regularly to prevent deterioration in cut quality

- Lubricate moving parts as needed to maintain smooth operation

- Conduct routine maintenance checks according to manufacturer guidelines

Safety Tips:

- Always wear appropriate safety gear, including eye protection, gloves, and closed-toe shoes

- Never leave the machine unattended during operation

- Keep the work area clear of any flammable materials or liquids

- Follow proper grounding procedures to prevent electrical hazards

- Keep the cutter machine away from moisture or humid environments

- Train all operators on professional use and safety procedures for the machine

Advancements in Fabric Laser Cutting Machine Technology

The technology behind fabric laser cutters continues to evolve, resulting in faster, more efficient, and more accurate cutters. Recent advancements in textile lasar cutting machine technology include:

- Integration of artificial intelligence for automated design and cutting processes

- Internet of Things (IoT) technology for remote monitoring and predictive maintenance

- Improved accuracy and precision through better control of lazer beam focus and intensity

- Development of specialized lazer cutting machines for specific fabric types and thicknesses

- Advancements in software and control systems for enhanced user interface and customization options

- Integration of new cutting technologies, such as waterjet cutting, to increase cutting capabilities

- The emergence of eco-friendly laser-cutting technologies that reduce waste production and energy consumption

- Integration of machine learning algorithms for better predictive maintenance and fault detection.

Common Applications of Fabric Laser Cutter Machines

Fabric laser cutting machines have a wide range of applications, including:

Fashion and Apparel Industry

Fabric lazer cutting machines are commonly used in the fashion and apparel industry to create intricate and complex designs on fabrics quickly and accurately.

Automotive Industry

Fabric lazser cutting machines are used in the automotive industry to cut fabrics used in the interior of vehicles, such as carpets and upholstery.

Home Decor

Fabric cutters are used in the home décor industry to create custom designs on fabrics used in curtains, cushions, and upholstery.

Conclusion

Fabric laser cutting machines are a valuable tool for anyone working with fabrics. They offer incredible accuracy, speed, and versatility.

Before buying a fabric laser cutters, consider factors like power, size, cutting area, speed, and maintenance requirements.

Proper maintenance and safety measures can ensure that your fabric laser-cutting machine lasts for several years, allowing you to explore endless creative possibilities.

Frequently Asked Questions (FAQs)

1. Can fabric lazer cutters cut through thick fabrics?

Ans: Yes, these cutter machines can easily cut thick fabrics, depending on the type and power of the machine.

2. How long does a fabric laser-cutting machine last?

Ans: The lifespan of a fabric lazer cutting machine depends on the type of machine, its usage, and the maintenance it receives.

3. Are fabric laser-cutting machines expensive?

Ans: The cost of a fabric lazer cutter depends on the type and features of the model machine. CO2 cutters are less expensive than fiber cutters.

4. Can fabric lasar cutting machines cut through all types of fabrics?

Ans: Fabric lasar cutting machines can cut through most fabrics, including cotton, silk, wool, and synthetic materials. However, some fabrics may require specialized settings or blades to cut through them.

5. What types of fabric materials are ideal for lasar cutters?

Ans: Lasar cutters are ideal for cutting a wide range of fabric materials, including

- Cotton

- Polyester

- Silk

- Leather

- Synthetic Fabrics

![Fabric Laser Cutting Machine From Scissors to Lasers [2023]](https://laserbeamcut.com/wp-content/uploads/2023/03/Fabric-Laser-Cutting-Machine-From-Scissors-to-Lasers-2023-1.jpg)