We use different materials to engrave custom designs on the surface. Laser engraving on plastic materials has gained significant popularity due to its versatility and precision. Plastics, including synthetic, semi-synthetic, and polymer materials, are ideal for laser engraving. It is due to their unique properties and widespread use in various industries.

It has the advantage of engraving complex shapes and forms. Traditional engraving methods are limited to flat surfaces. The laser machines can effectively mark and etch intricate designs on molded plastic components. It enables business owners and DIYers to create visually appealing and personalized plastic products.

Another advantage of this technology to engrave plastics is its compatibility with flexible thin sheets. It makes delicate and intricate engraved designs on engineered plastics without compromising their structural integrity.

It is crucial to choose the right plastic type for laser operations. Certain plastics may produce toxic by-products when vaporized by the laser beam. It causes health risks and compromises the quality of the engraving. The selection is crucial to achieve optimal results and to ensure the safety of the workplace.

The purpose of this article is to discuss various aspects of laser engraving on plastics. We will discuss suitable plastic types for the process and methods to improve the overall quality of the engraving. By understanding the specific properties of each plastic, such as its melting point, thermal conductivity, and coloration, one can determine the most suitable settings for laser engraving. This knowledge enables professionals to achieve precise and visually appealing results while working with different types of plastics

What Is Laser Engraving Plastic?

Laser engraving is a highly efficient and precise process that can engrave various types of plastics using lasers. The process involves using different types of lasers such as diode lasers, fiber lasers, and CO2 lasers. And each comes with its specific power rating and capabilities.

The selection of a laser machine plays a crucial role in achieving the desired results. For instance, low-powered lasers are suitable for engraving thin plastic materials. On the other hand, high-powered lasers are best for thicker plastics.

The laser engraving process is fast and economical. It makes it an ideal choice for various applications. It is possible to achieve engraving in a single pass by selecting the right machine and its power settings. In some cases, there may be a need for multiple passes in order to achieve the desired engraving level.

There are various plastic types available in the market. Laser is not suitable for each plastic type. So let’s move to understand their types. And learn which are engravable plastics.

Types of Plastics Suitable for Laser Engraving

Plastics are synthetic materials made from polymers, which are long chains of molecules. They are versatile and can be molded into various shapes and sizes when heated.

When it comes to laser engraving plastic, various types of plastics can be effectively utilized in laser processing. Among these plastics, Acrylic, Fluoropolymers, Delrin, Polycarbonate, Mylar, and Polyimide offer exceptional results. Laser engraving is a safe and precise method for creating intricate designs and patterns on these plastic materials.

Acrylic

Acrylic is a thermoplastic material. It uses in various industries. And it is an excellent choice for laser engraving due to its unique optical properties.

It offers several advantages, such as clean processing without toxic fumes. That can cause health irritation to the lungs.

When selecting the type of acrylic for laser engraving, two common varieties are often referred to:

- Cast Acrylic

- Extruded Acrylic

Cast acrylic produces superior results due to its smooth and evenly distributed composition. On the other hand, extruded acrylic is a cheaper alternative that engraves smoothly but may exhibit a slightly grayish shade in comparison.

These are also types of acrylic plastics but are not common for engraving tasks.

- Lucite

- Mirrored Acrylic

- Plexiglass

Fluoropolymers

Fluoropolymers are plastics that exhibit unique properties due to the carbon and fluoride bonding within their molecular structure. These materials are highly suitable for laser engraving applications. The CO2 laser is considered the best option for engraving fluoropolymers.

There are various further types of fluoropolymers.

- Teflon

- Kel-F

- Halar

Selecting the right wavelength laser and its power settings is crucial to achieving the desired engraved results. These are thermally stable and chemically resistant. Due to these properties, these are particularly suitable for deep engraving applications.

As a result of their inherent properties, they can be engraved to produce sharp, well-defined markings. That is precise and intricate. Moreover, fluoropolymers have a smooth and aesthetically pleasing surface finish after engraving.

Delrin

Delrin is known as polyoxymethylene (POM) or poly acetals. It is a thermoplastic that belongs to the family of high-strength plastic materials. Due to rigidity and low friction properties, it is an ideal material for various applications.

When it comes to laser engraving, Delrin proves to be a suitable choice due to its compatibility with both CO2 and fiber lasers. It can absorb laser energy efficiently at their specific wavelengths. And it enables precise and smooth engraving cuts during the engraving process.

One of the advantages of using Delrin for laser engraving is its excellent finishing capabilities. Due to this, it is an appealing option for engraving intricate designs and detailed patterns on various objects.

Due to their high strength properties, Delrin’s are used in bearings, pumps, and gears. It is possible to mark or engrave these products using lasers.

It is crucial to consider the potential emission of fumes when working on Delrin with the lasers. These can release gases, including formaldehyde gas. That can be toxic and unpleasant. Therefore, it is crucial to have proper ventilation systems in place to ensure a safe working environment.

Polycarbonate

Polycarbonate is a thermoplastic material. It is widely recognized for its excellent properties. It is a possible choice for laser engraving applications. With its high impact resistance and durability, it offers great potential for engraving intricate designs. When it comes to laser engraving, the type of laser used is crucial. And a CO2 laser with the appropriate wavelength is ideal for working with polycarbonate.

Types of polycarbonate are

- Lexan

- Lupoy

- Makrolon

These variants possess a high level of detail and exhibit good results when engraved using a low-power laser. Additionally, their carbonate content ensures durable and long-lasting labels.

However, it is important to consider certain factors while laser engraving polycarbonate. Yellowish discoloring may occur during the engraving process. It may also produce smoke during the process. To minimize these effects, precautions should be taken. Adjusting laser parameters and using appropriate ventilation systems can help these challenges.

Laser marking is another technique that can be employed on polycarbonate using a fiber laser. This method yields excellent results with high levels of detail. It ensures precise and permanent markings on the material’s surface.

Mylar or Polyester

Mylar is a type of polyester film. It is commonly used in laser processing applications, particularly in CO2 laser systems. Its unique properties make it an ideal material for laser cutting, marking, and engraving. The CO2 laser, with its specific wavelength, is well-suited for working with Mylar.

The focused laser beam effortlessly slices through the material. It produces clean cuts and accurate edges. This process is especially useful for creating intricate designs and complex shapes on Mylar surfaces.

When Mylar is marked or engraved using a CO2 laser, it undergoes a surface transformation. The laser beam interacts with the material, altering its appearance and leaving a permanent mark. The result is a high-quality and professional finish that enhances the visual appeal of Mylar products.

One of the key advantages of using Mylar in laser processing is its exceptional structural integrity. Despite its thinness, Mylar exhibits high tensile strength. It enables it to withstand the laser cutting process without tearing or distorting. This attribute ensures that the final product maintains its shape and durability.

In laser engraving, Mylar stencils are commonly employed for creating repetitive patterns or designs. These stencils, made from Mylar sheets, are precisely cut using a CO2 laser. The laser cutting speed can be adjusted to achieve the desired level of detail.

When working with Mylar, it is crucial to take into account the laser parameters and settings. Excessive laser power should be avoided to prevent edge burns. And avoid unintended melting of the material to save its internal strength.

Polyimide

Polyimides, such as Kapton, are a class of thermosetting polymers. These have various industrial applications due to their exceptional properties. One application where they excel is laser engraving. It particularly when utilizing a CO2 laser. Laser processing with a CO2 laser offers precise and efficient cutting and marking capabilities. It makes it suitable for working with polyimide materials.

These have high chemical resistance properties. It ensures material integrity during laser engraving. Polyimides are excellent electrical-resistant plastics.

Polyimides offer good mechanical properties for precise and intricate engraving. Laser engraving on polyimides allows for creation of precise solder masks and stencils.

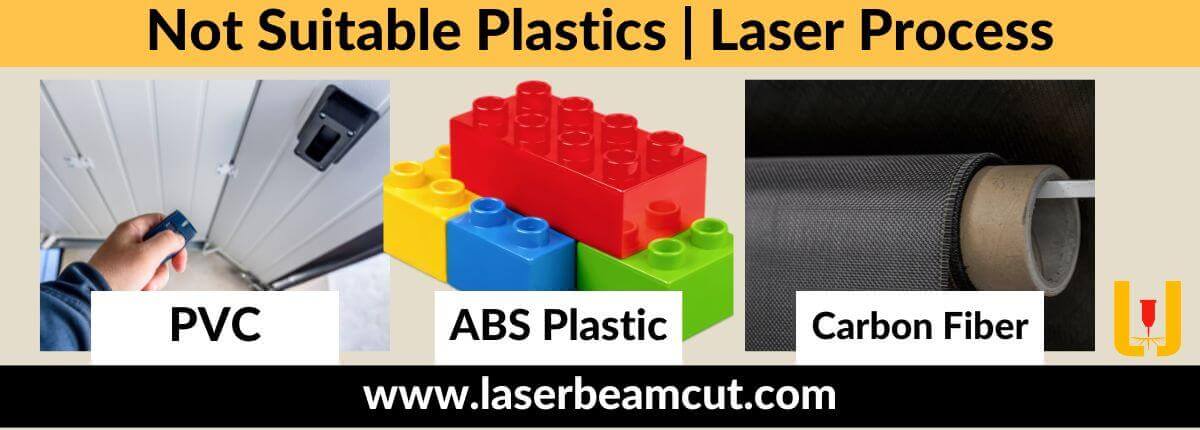

Types Of Plastics Not Suitable For Laser Engraving

When it comes to laser engraving, it is crucial to be aware of the types of plastics that are not suitable for this specific type of laser processing. Laser engraving involves using a laser beam to etch designs or patterns onto a material.

However, not all plastics are compatible with this process. And using the wrong type of plastic can lead to various hazards and laser safety risks.

PVC

Polyvinyl chloride (PVC), a widely utilized thermoplastic material. It holds a prominent position among the various industries. It plays a crucial role in sectors such as healthcare, electronics, and plumbing, offering immense benefits. The inherent strength and remarkable versatility of PVC make it highly suitable for various applications that find their way into our daily lives. PVC finds extensive utilization in the manufacturing of essential items like pipes, wire insulation, blood storage bags, flooring, and synthetic leathers.

When it comes to laser engraving, PVC with a high vinyl content can pose certain challenges and risks. The process of laser engrave PVC can generate harmful fumes due to the presence of chlorine in the material.

As the laser beam vaporizes the PVC, it releases chlorine gas and hydrochloric acid. That can be damaging if inhaled. Therefore, it is essential to handle PVC and laser equipment with caution to avoid potential health hazards.

ABS Plastic

ABS is called Acrylonitrile Butadiene Styrene. This thermoplastic is used in various industries. It offers excellent durability and impact resistance. That makes it suitable for a range of applications. When it comes to laser operations, ABS plastic presents certain limitations. Although it can be cut, engraved, marked, or etched using a low-power laser. It is not the ideal material for such processes.

One of the challenges with laser engraving ABS plastic is its tendency to melt under high temperatures. The laser’s intense heat has the potential to transform ABS into a gooey mess, a molten state. As the result, it gives imprecise markings and poor engraving quality.

Moreover, the melting process often produces fumes. That can be irritating to the eyes, skin, and lungs. It requires appropriate safety measures to be in place.

Carbon Fiber

Carbon fiber is a remarkable material. It is known for its exceptional properties in engineering and manufacturing. Composed of thin, lightweight polymer strands, and carbon fiber. It exhibits an outstanding combination of strength and stiffness. And it makes it highly sought after in various industries. This advanced composite material owes its superior performance to the unique arrangement of carbon atoms. Resulting in a structure that surpasses traditional materials in terms of weight-to-strength ratio.

In terms of safety, carbon fiber, when properly handled, exhibits a favorable tendency concerning fire. Unlike certain plastics, which are prone to catching fire and releasing harmful fumes. Carbon fiber is inherently fire-resistant. Although carbon fiber itself does not burn.

It is essential to note that the epoxy coating used to protect the fibers may be susceptible to heat. Therefore, proper precautions and expertise in laser processing techniques are necessary to prevent any potential risks.

How to Engrave Plastics by Laser Machines?

Laser engraving is a highly effective method for engraving plastics. As it utilizes a laser beam to generate controlled heat. The intense heat causes the plastic to evaporate. Then it leaves behind a deep and precise engraving of the desired designs.

When considering laser engraving plastics, it is crucial to take into account various machine parameters to attain the most precise results. These parameters are

Laser Power

When it comes to laser power, different types of lasers offer varying levels of intensity and capabilities for cutting, engraving, and marking various materials. Laser power is measured in watts. This parameter plays a crucial role in determining the efficiency and effectiveness of laser processes. For instance, CO2 lasers (30 or above watts) with high power ratings are suitable for engraving, etching, and cutting operations.

When it comes to engraving plastics using laser machines, the choice of laser power is crucial. The recommended power rating for plastic engraving depends on factors such as the type of plastic and the desired depth of the engraving.

Engraving, etching, and cutting of plastics need a change in plastic surface. So high-power CO2 lasers are recommended for these operations. On the other hand, fiber lasers with lower power ratings are often suitable for only marking plastics.

Laser Wavelength

Laser wavelength plays a crucial role in various applications, including the engraving, cutting, and marking of plastics. The selection of the appropriate laser wavelength is essential to achieve optimal results in laser processing. Different types of lasers (CO2 and fiber) are used for these purposes, each with its unique characteristics.

The recommended range of CO2 lasers is between 9.5 µm to 10.6 µm to engrave or cut plastics. For marking plastics, 1.06 µm of fiber lasers are best.

Speed

When it comes to the topic of speed in the context of laser processing on plastics, several factors play a crucial role in achieving optimal results. The laser speed is one such factor that significantly affects the overall process.

Laser machine depends on laser power, material thickness and material type. Slow speed gives precise and smooth engrave cuts. But it may takes time for mass production.

For cutting plastics, 5 mm/s is a good speed for 5 mm thick plastic materials. And for engraving plastics, 300 mm/s is a good speed with 15% laser power.

Working Table

Working tables play a crucial role in various industries. Especially those that involve laser processes such as cutting, engraving, etching, or marking transparent plastics. Laser-cutting is a highly precise technique used to shape and carve intricate designs on different materials. When it comes to transparent plastics. Engraving can pose specific challenges that need to be overcome to ensure flawless results.

One common issue encountered during laser engraving on transparent plastics is a flashback. It is due to the unwanted reflection of laser beams. This phenomenon can lead to defects in the workpiece. Hence, it affects the overall quality of the engraving. To mitigate this problem, an appropriate choice of the working table becomes essential.

One effective solution to reduce the chances of flashbacks and defects is the use of a honeycomb table. The unique design of a honeycomb table allows for efficient laser-cutting of transparent plastics.

Air Assist

Air assist is an essential component in laser cutting and engraving plastic. The use of low-pressure air assist is highly recommended in this process.

By incorporating low-pressure air assist, the laser beam can effectively cut through or engrave the plastic material while keeping the temperature under control. It ensures that the plastic maintains its structural integrity and prevents any undesirable effects, such as warping or melting.

During laser-cutting, the low-pressure air assist creates a protective barrier between the laser beam and the plastic surface. This barrier not only cools down the temperature but also helps to remove any debris or particles that may form during the laser process.

One of the advantages of utilizing low-pressure air assist in laser-cutting plastic is the formation of a flame polished edge. As the laser beam interacts with the plastic, the air assist assists in refining the edges, resulting in a smooth and polished finish. That is particularly important when working with transparent or translucent plastics.

Exhaust System

When utilizing laser cutters for engraving plastics, it is essential to consider the various types of exhaust systems. These release fumes and vapors that can be unpleasant.

And these fumes and vapors may harm humans. Therefore, a good exhaust system with laser machines is necessary to counter these risks.

Applications of Engraved Plastic

It uses in various industries for identification purposes. It uses to engrave the Photos, Text, Symbols, or Brand Logos on various plastic products. We can use laser engraving plastic for many industries like

- Use to label identification codes, product information, and safety warnings on industrial products

- To make customized gifts for our loved ones by name, logos, and wishing messages engravings.

- For the packaging industry to engrave logos and product information

- Use to engrave directional signs, room numbers, and building information

- Use to engrave identification codes and symbols on plastic car parts and accessories.

- Use for Medical devices such as serial numbers, product information, and safety warnings.

- Used for DIY arts and Crafts projects.

Best Laser Machines for Plastics

- The best laser engraver machines for plastic materials are:

- Glowforge Plus

- OMTech DF0812-40BG

- Beamo-FLUX

Summary

Laser engraving has revolutionized the plastic industry with its precise and intricate cuts. It offers a wide array of creative possibilities.

Plastic, known for its durability and availability in various colors. And it is an ideal material for laser cutting and engraving. This advanced technique allows industries to accomplish complex cuts with remarkable accuracy. It enhances the nature of their projects. The laser process depend on the appropriate type of plastic and ensuring laser safety by wearing protective glasses.

Operating a working laser machine, equipped with an efficient exhaust setup, guarantees optimal results. Ultimately, laser engraving on plastic presents a profitable opportunity for businesses seeking innovative and visually appealing solutions.

FAQs (Frequently Asked Questions)

1. What is a flashback?

Ans: A flashback in laser engraving plastic refers to the unintended burning or melting of the material behind the intended engraving area due to reflected laser energy.

2. What plastic is best for laser engraving?

Ans: The best plastic for laser engraving is acrylic (PMMA) and polypropylene (PP). These plastics yield the best results when laser-cut, producing smooth, shiny edges without any scorch marks. Therefore, both acrylic (PMMA) and polypropylene (PP) are suitable choices for laser engraving.

3. Can you laser engrave plastic tumblers?

Ans: Yes, you can laser engrave plastic tumblers.

4. Can a laser melt plastic?

Ans: Yes, a laser beam can melt the plastic. Some plastics are not strong enough to bear the heat. Use low-power engravers instead of high-power engravers for such materials.