When working in our work areas or industries, we need to label tools and parts for identification purposes. These labels should preferably be permanent to prevent wear. We have many options to mark these labels for identification purposes, and Dot peen marking machine is one solution of them.

The Dot peen labeling system is known as the “Pin Stamping” method. It uses a machine-tool tungsten carbide pin to produce marks on materials by striking them directly with this tool. These marks can be readable by humans and machines.

In the article, you will learn about the dots matrix labelled system and its comparison to laser-markings. In the end, you’ll be able to decide which label system is best for your job. Are you ready? Let’s get started.

Marking Systems:

In the manufacturing market, you can mark your products with various methods. Some include laser-markings systems, dot peening, and chemical markings. In most cases, lasers and dots matrix labelled systems are the best options for industries due to their various benefits. Let’s discuss these two methods in detail.

Dot Matrix or Pin-Marked Systems:

This marking system uses a machine tip made of rigid carbide, which is pressed against the material to create tiny holes. These marks are easily traceable and are permanent.

Lasers Marked systems:

Laser marking uses a high-power lasers on the surface to alter the material properties to left marks on it.

Dot Peen Marking Machine:

A dot peen marker machines are also known as a dot matrix markers or a pin markers. It is a machine that uses a pointed tip to create a permanent mark on a material surface.

This machine includes a movable arm that holds the pointed tip, typically made of tungsten carbide. With the help of a computer-controlled system, the “Tip” is manipulated in a specific pattern to make the mark you want.

History:

The first pin marker machines were mechanical devices that used a pointed tip to indent the surface of a material. These early devices were manual and required the operator to move the tooltip manually to create the desired marks.

Over time, dots matrix label technology has evolved and become more automated. In the 1960s and 1970s, electromechanical dots matrix label devices were introduced, which used an electric motor to move the pointed tip. These devices were more efficient and precise than their mechanical counterparts.

In the 1980s and 1990s, computer-controlled dots matrix mark devices were introduced, which allowed greater control and flexibility in the labelling process. These devices use a computer-controlled system to move the pointed tip in a specific pattern to create the desired mark.

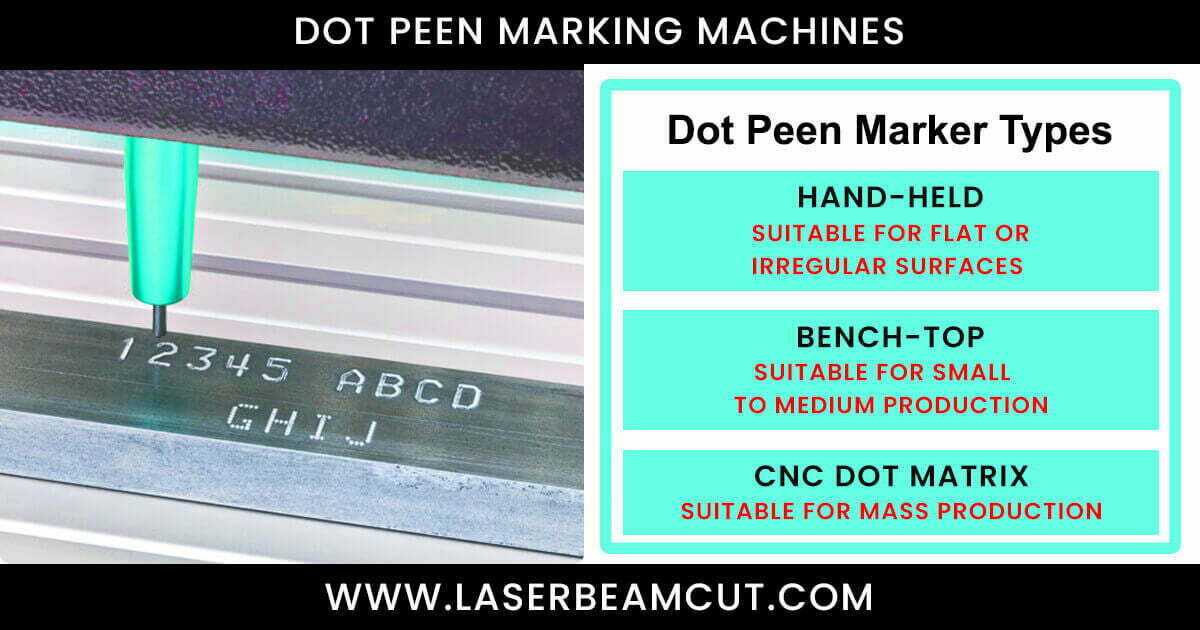

Types of Dot-Peen or Pin Markers:

There are several types of dots matrix marker devices, which can be broadly classified based on the labelling method of operation and the material type.

Hand-held Pin Marker Machines:

These are portable machines; that can be hand-held and used to mark a wide range of materials. They are commonly used for small scale label tasks and are suitable for flat or irregular surfaces.

Benchtop Pin Marker Machines:

A benchtop machine mounted on a table or workbench. Benchtop dots matrix labeling-machines are suitable for small- to medium-volume label applications. They offer a cost-effective and reliable label solution with high-quality results.

CNC Pin-marker machines:

Machines that use computer numerical control (CNC) systems move their pointed tips in a specific pattern to create marks. They are suitable for mass production marking-applications and industries where high precisions are needed: such as aerospace, automotive, and manufacturing.

Comparison of Pin Markers Machine VS Lasers Markings System:

Dots matrixs labeling machines and lasers labeling are both used to create permanent marks on materials. Both technologies have unique characteristics and are suitable for different applications. Here is a comparison of dot-pin mark devices and lasers mark systems:

Parameter | Dot-pin Marking-Methods | Lasers-Marking Methods |

Mark method | It uses a pointed tip to indent the surface of a material. | It uses a lasers beam to label the surface. |

Mark quality | It can produce high-quality marks on certain materials, such as metal, plastic, and composites. But low as compared to lazers marking-methods. | It produces higher-quality marks with finer details and a smoother surface finish. |

Mark speed | These devices require more time to operate than lasers marking-machines. | These are generally faster than dot-peen devices, especially for high-volume labeling applications. |

Material compatibility | The devices are primarily suitable for markings on metals and plastics. These devices can create deep marks. | It can label many materials, but some are not possible due to lasers beams. |

Maintenance | It may require frequent tip replacement. | It generally requires less maintenance. |

Conclusion:

In conclusion, the choice between a dots matrixs marked devices and the lasers marked systems depends on the specific mark requirements, including the material type, the mark quality and speed needed, and the marked depth required. Both technologies have strengths and limitations, and the best choice will depend on the specific application.

In this article, you learn about doted peen markers that uses a pointed tip to indent the surface of a material. It can be any barcode, symbol, or text. In the end, We compare this with the lasers marked system, and we conclude that both have strengths and limitations, and the best choice will depend on the specific application.

Frequently Asked Questions (FAQs):

1. Why do we choose dot peen marking machine?

This labeling system enables you to get deep marks on material surfaces, while other methods like labeling by lasers have limitations.

2. What are the benefits of dot-pin markers?

These marking-machines have a lot of benefits. Some are listed below:

- Hard materials are possible by these markers.

- Portable device

- Produces Permanent marks

3. What is Pin-Marking or dot-peen labeling?

In dots matrixs or pin-markers, a pointed pin-tool of carbide material is a pin-type tool that strikes the material surface to left marks by leaving holes.

4. How can we choose our labeling system for our job?

There are several labeling systems available in the market for identification purposes. Each device type has strengths and limitations, so we can choose by considering a few parameters, such as the material type, the labeling quality and speed needed, and the mark-depth required.