Laser marker machines are of various types based on the lasers used in them. Each one has unique purposes and pros and cons. In this article, we will discuss CO2 VS fiber laser marking.

CO2 machines mark non-metallic materials. And Fiber lasers mark metallic materials. Certain reflective metals, like copper, are not easy to label with fiber lasers. We can label them with UV lasers.

This article covers deeply comparison between CO2 VS Fiber laser marking. By the end of this reading, you will be able to determine the best machine for your specific needs.

Which laser types do marker machines use?

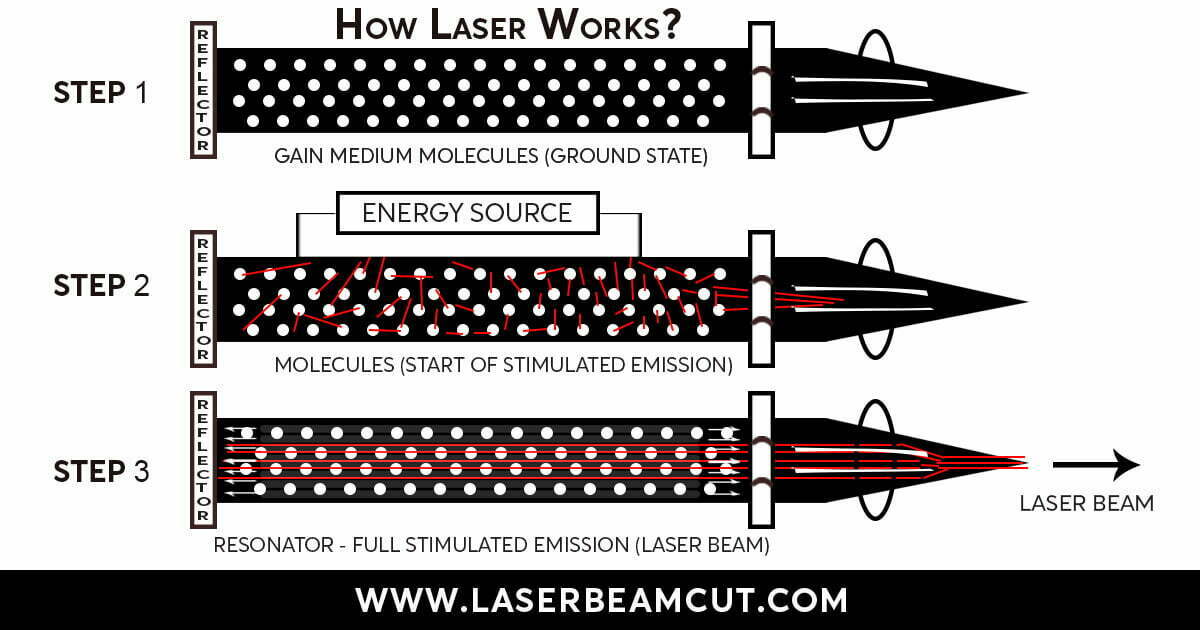

Lasers are light amplifier devices that emit coherent, monochromatic, and one-directional light beams.

These devices depend on energy sources that use in the gain medium. Marker machines use five types of lasers.

- Gas Lasers (CO2-Carbon dioxide)

- Solid state

- Fibers or Galvo lasers

- Dye or Liquid laser-devices

- Semiconductor laser-device

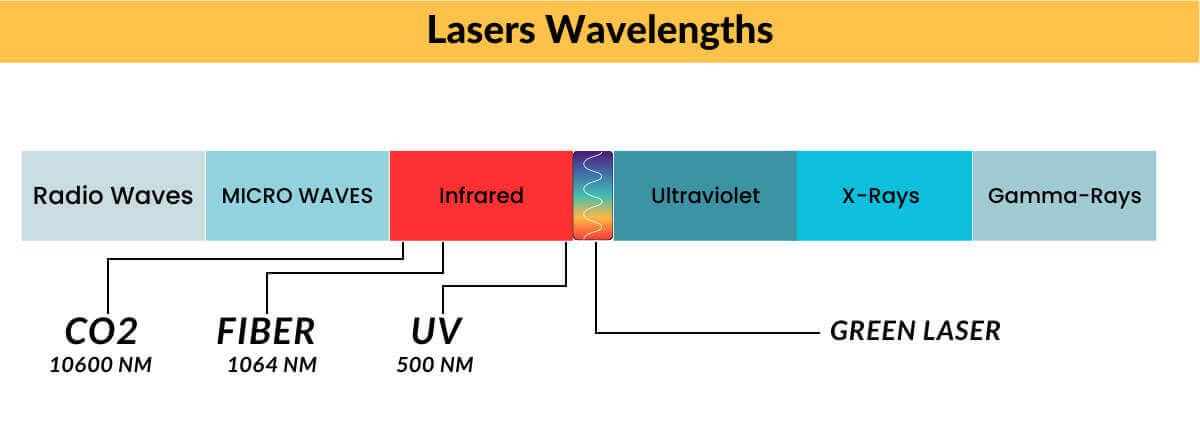

Marking quality and feasibility depends on these types. Each type has a specific wavelength.

These wavelengths determine the machine’s working compatibility and feasibility on various applications.

CO2-Laser

This technology has been in use since the 1960s and is well-established. These lasers have wavelengths of around 10,600 nm.

As their wavelengths are high in range, these cannot be effective for hard and reflective materials. It usually uses to mark non-metals.

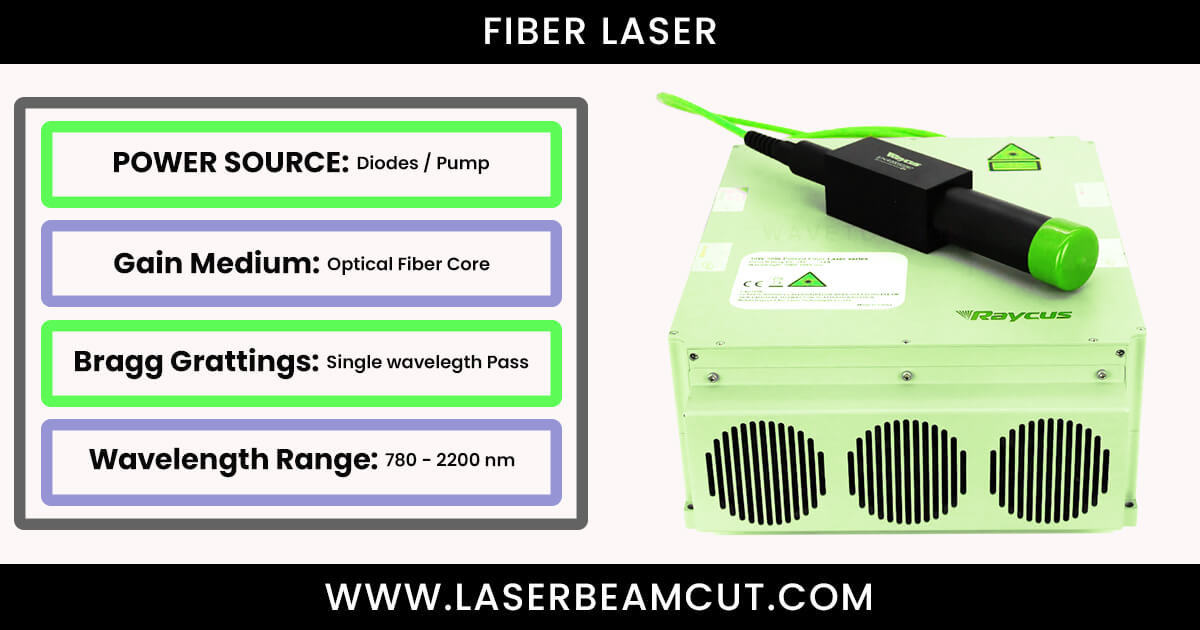

Fiber-Laser

Fiber laser marking technology started in the 1990s. These lasers have a wavelength of around 10,64 nm.

These galvo lasers are ideal for working on metal markings. Some highly reflective metal labeling is not possible with fibers. We can use UV lasers to mark such materials. The wavelength of UV lasers is around 500 nm.

Read: We have a blog about lasers and their classifications based on safety norms.

Comparison of CO2 VS Fiber Laser Marking

Laser marking with CO2 and fiber lasers is popular, but they differ in several crucial ways. CO2 VS fiber labeling differ in the following ways:

Wavelength:

Carbon-dioxide lasers have a wavelength of around 10,600 nm (10.6 microns) compared to fiber lasers, which have a wavelength of about 10,64 nm (typically around 1 micron).

This longer wavelength makes Carbon-dioxide lasers better suited for labeling and engraving non-metallic materials like wood, glass, and plastics.

Fibers are better suited for metal labeling and engraving.

Marking speed:

Due to their higher power density and smaller beam size, fibers are typically faster than Carbon dioxide lasers for labeling.

It makes fibers more efficient for high-volume production environments.

The fiber 20 Watt machine is marked 3X times faster than 60 Watt Carbon dioxide marker machine.

Maintenance:

Carbon dioxide lasers have a higher maintenance requirement than fiber lasers. Fiber lasers, on the other hand, have a longer lifespan and require minimal maintenance.

Cost:

Generally, fiber lasers are more expensive than Carbon dioxide lasers because of their more complex technology and higher diode costs.

Marking quality:

Fiber lasers produce more precise and higher contrast marks, particularly on metals, than Carbon-dioxide lasers. But Carbon-dioxide lasers can create high-quality markings as well on non-metallic materials.

Ultimately, Carbon dioxide or fiber marking depends on the specific application requirements.

Conclusion

CO2 VS fiber marking has different advantages and disadvantages. CO2 lasers are better for non-metallic materials, while fibers are ideal for metals.

Fibers are faster and need less maintenance. However, Carbon-dioxide lasers are less expensive and have a long history of use.

Materials, marking quality, speed, and budget all play a role in determining the choice between the two.

FAQs of CO2 VS Fiber Laser Marking

1. Are CO2 laser results permanent?

Yes, Carbon dioxide laser results are permanent as the laser removes material from the surface, creating a permanent mark or engraving.

2. What are the limitations of CO2 laser in marking materials?

Carbon-dioxide lasers have limitations in labeling some materials, such as metals. These may not be as precise as other laser types.

3. What is the advantage of fiber laser in marking?

Fibers are advantageous in labeling metals due to their high precision, speed, and ability to produce high contrast marks.

4. Can fiber laser mark on stone?

Marking stone does not involve fiber marks. The composition and structure of the material make it difficult to label using lasers.

5. What is the main difference between CO2 VS Fiber Laser Marking?

The main difference between Fiber and Carbon-dioxide labeling is the type of materials they can mark. Carbon-dioxide lasers can label non-metals, while fiber lasers are ideal for metallic material markings.