We have a lot of methods to engrave material designs. To engrave materials, we can use a CNC engraver or Laser engraver. Both have their Pros and Cons. Discover the differences between CNC VS Laser engraving techniques.

With CNC engraving, designs are carved into materials using a computer-controlled cutting tool. Alternatively, lasers engraving involves burning or vaporizing materials to create detailed designs using a high-powered lasers.

In this article, We will compare these Engravings in detail and help you decide which is best for your project based on the differences and similarities we discuss.

What are CNC Engraving and Laser Engraving?

Laser engraving uses laser beam to vaporize material surface and left deep marks on it. We can do Color Engravings by these engravers.

Read: You can read our blog about laser engraving by clicking here: “What is Laser Engraving in detail?.”

CNC engraving, short for Computer Numerical Control, is a process that uses a computer-controlled cutting tool to carve designs into the material surface. Design software determines how the cutting tool should move along a specific path or contour.

These engravers can work on various materials such as wood, metal, plastics, and many more.

It is a popular choice for industrial parts, signs, nameplates, and other applications requiring high accuracy and repeatability. Besides engravings, Computer Numerical Control machines can also cut and shape material, making them versatile prototyping tools.

Advantages

High precision:

These machines are excellent at being precise and accurate, which is essential for creating intricate designs and patterns. They are ideal for mass production and creating identical parts because they can repeat the same design pattern with minimal variation.

Efficiency:

Computer Numerical controlled engravers can work quickly and can finish large projects in a shorter time than other methods. Additionally, they can work continuously without human intervention, which increases productivity.

Versatility:

Computer Numerical controlled engravers can work on various materials such as wood, metal, plastics, and many more. In addition to cutting and shaping material used for prototyping.

Cost-effective:

CNC engraver can be cost-effective in the long run, as they can work on multiple material types and create designs with a high level of precision. And the manual work would waste time and materials.

Computer-controlled:

CNC engraver machines are computer-controlled, which allows for easy editing and manipulation of designs. Moreover, It gives more design flexibility and changes.

Applications

Industrial parts:

Various industrial parts such as gears, molds, dies, and other components are engraved using Computer Numerical Control engravers.

Signs and nameplates:

It is possible to create detailed, attractive signs, nameplates, and other identification products using CNC engraver machines.

Awards and Trophies:

Awards, trophies, and other recognition products are engraved using Computer Numerical Control engravers.

Jewelry:

Jewelry items such as rings, bracelets, and pendants are engraved using Computer Numerical Control machines.

Personalization:

We can personalize pens, keychains, and other small items with Computer Numerical Control engravers.

Prototyping:

To create prototypes and models of products in various industries such as aerospace, automotive, and more, we can use Computer Numerical controlled Machines.

Woodworking:

Wooden items, such as furniture, cabinetry, and decorative items, can be engraved with detailed designs using the Computers Numerical controlled engraver machines.

Glass and stone:

Using the computers numerical controlled engraver machines, you can engrave designs on glass and stone.

Comparison of CNC vs Laser Engraving

On various materials, laser engravings and CNC engravings are two popular techniques. Both technologies have unique advantages and are suitable for different types of projects.

Similarities:

- Both engraving machines are precise and accurate: which is essential for creating intricate designs and patterns.

- Materials such as wood, metal, plastic, and many more are best to work on these machines.

- Both are computer-controlled, which allows for easy editing and manipulation of designs.

Differences:

CNC Engravings:

- It uses a cutting tool, which physically removes material from the surface.

- Software typically uses vector-based design software, such as AutoCAD or CorelDRAW, to create designs.

- The software converts the design into machine-readable code, which the CNC machine uses to control the cutting tool and create the design on the material.

- Cuts and shapes materials.

- Computer Numerical Control engraver is faster and can handle larger projects

- Best for mass production and creating identical parts

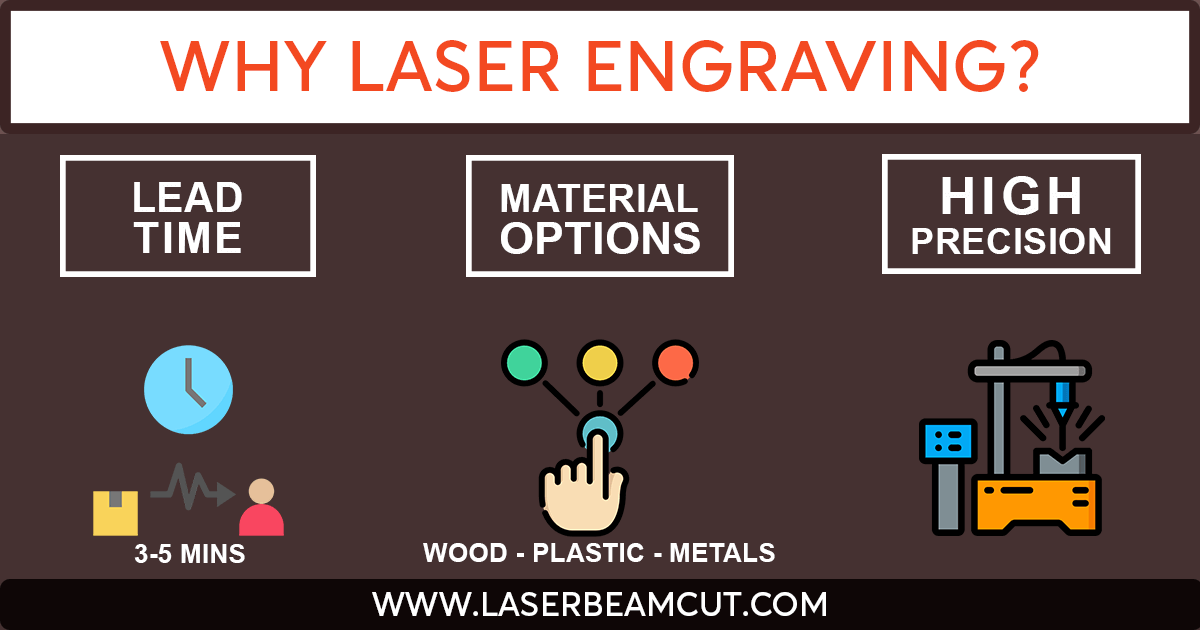

Laser Engravings:

- It uses a high-powered lazer beam to burn or vaporize the material.

- Software typically uses raster-based design software, such as Adobe Photoshop or Illustrator, to create designs.

- Additionally, the software allows for the creation of lazer paths, which control the lasers movements and burn intensity.

- Use to engrave or mark the material surface.

- It is better for fine details and minimal material removal.

- Best for personalization and smaller projects.

Conclusion:

Now you have a clearer picture of CNC VS Laser engraving. In conclusion, both engravings are powerful technologies that can create intricate designs and patterns on various materials. Computer Numerical Control engravings are a versatile technology that can handle a wide range of material types and is suitable for mass production. And lazer engravings are a precision technology that excels at fine details and personalization.

Both technologies have unique advantages, and the choice between the two depends on the nature of the project and the desired outcome.

Computer Numerical Control engravings may be the best option for industrial parts, signs, nameplates, and cutting and shaping materials. And lazer engravings may be the best choice for fine details, personalization, and jewelry.

FAQs (CNC VS Laser Engraving)

1. Which machine is best for engraving materials, a CNC machines or a laser?

CNC machine is best for cutting and shaping materials and mass production. And Lasers are best for fine details and personalization.

2. Which machine is best for DIY projects, a CNC machine or a lazer?

The best machine for DIY projects depends on the complexity of the project and the desired outcome. Lazer machines are generally more accessible for DIY projects due to their lower cost and ease of use.

3. What type of software do CNC machines use to operate?

Computer Numerical Control engravers typically use specialized software called CAD or CAM.

4. What is the future of CNC engraving and lasers?

The future of CNC engravings and lasers looks promising with advancements in technology. Both techniques will become more precise and versatile as they become more efficient, making them suitable for new materials and applications.

5. What are the pros of CNC engravers?

Material flexibility, simple setup, and secure design offer deeper, long-lasting engravings.